Anyone been down this road yet?

Viper T56

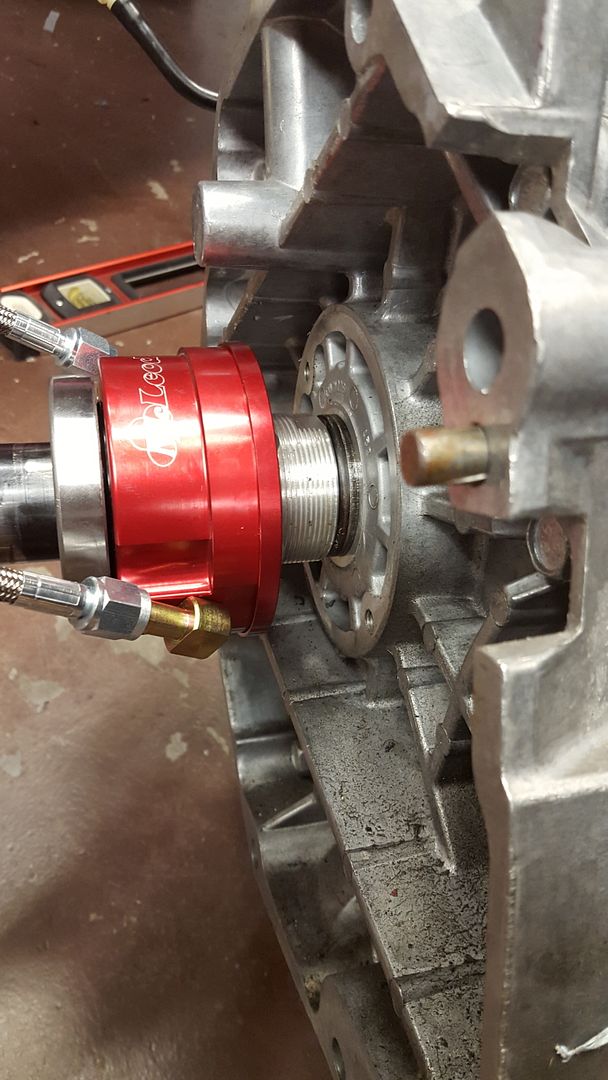

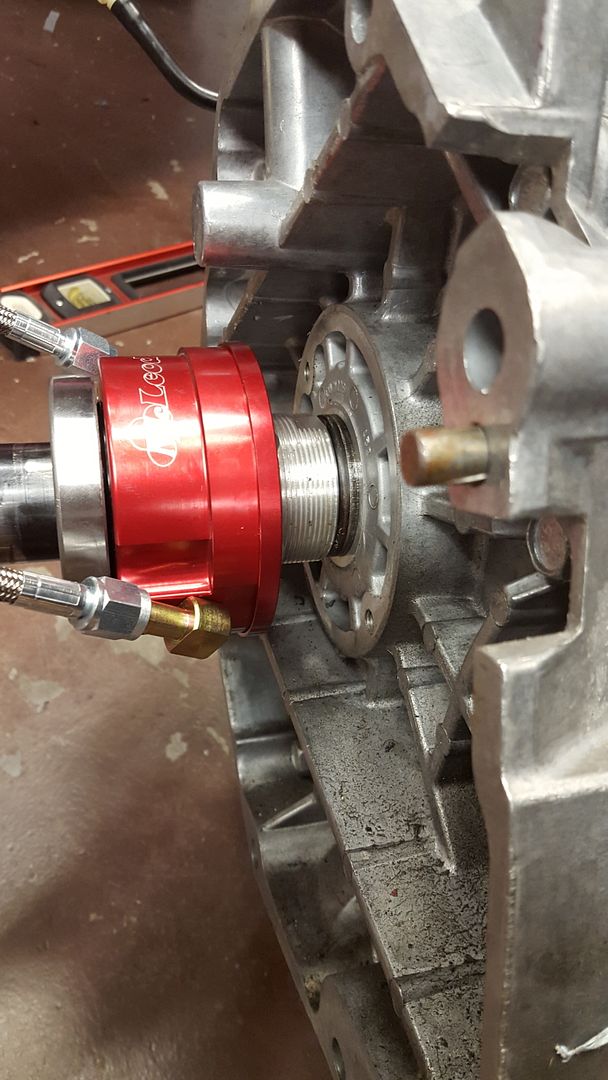

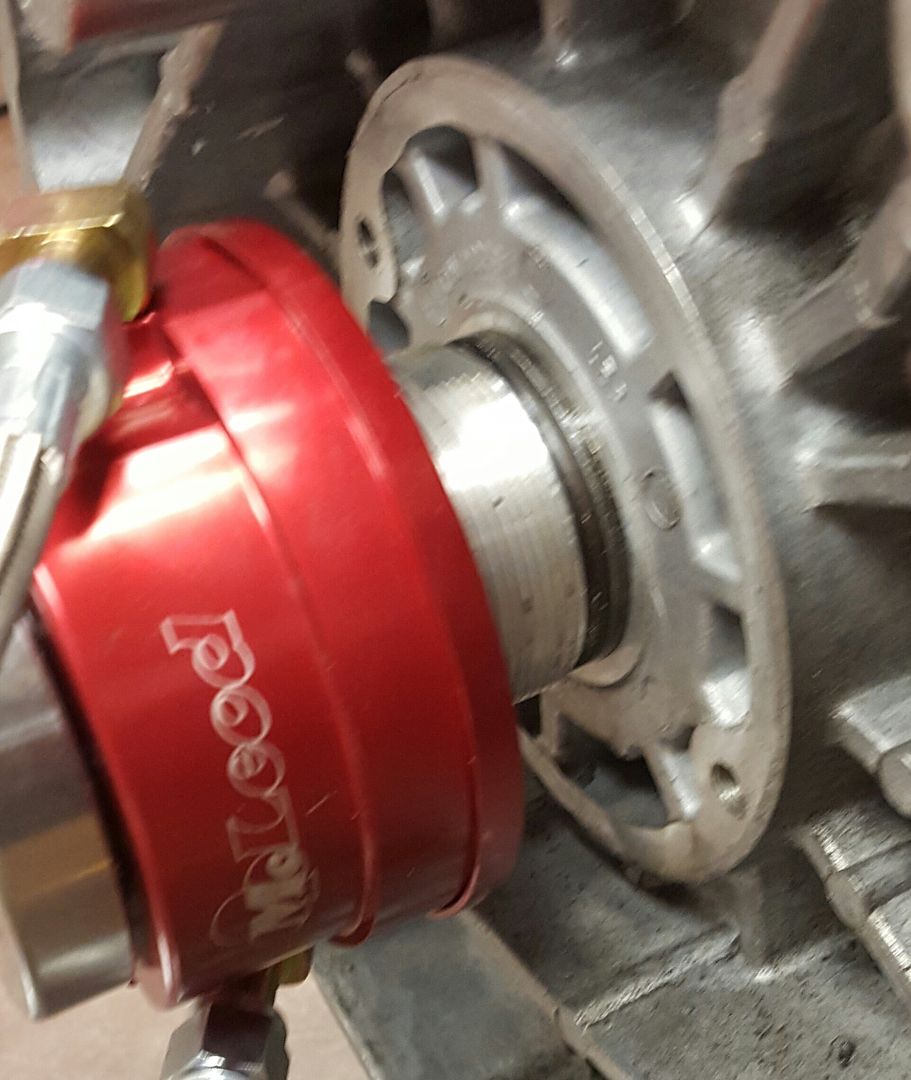

McLeod hyd throwout bearing....fully threaded IN the bearing face is 1.725" from face of trans which is 1.3"+/- from the fingers

Custom twin disc.....fingers are 3.06" from face of trans.

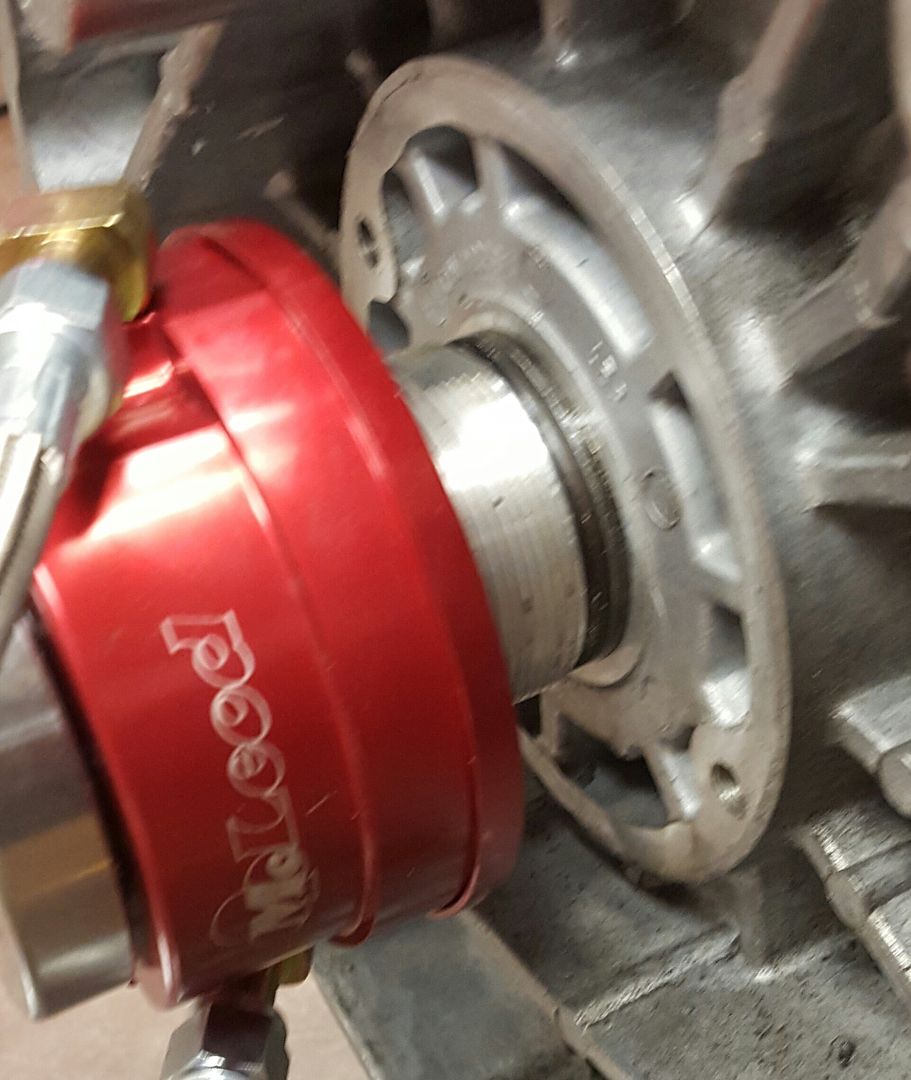

The bearing gets .06" closer with every turn on the adapter sleeve. At my measurements it would take about 23 turns to give me the .100" - .150" gap.

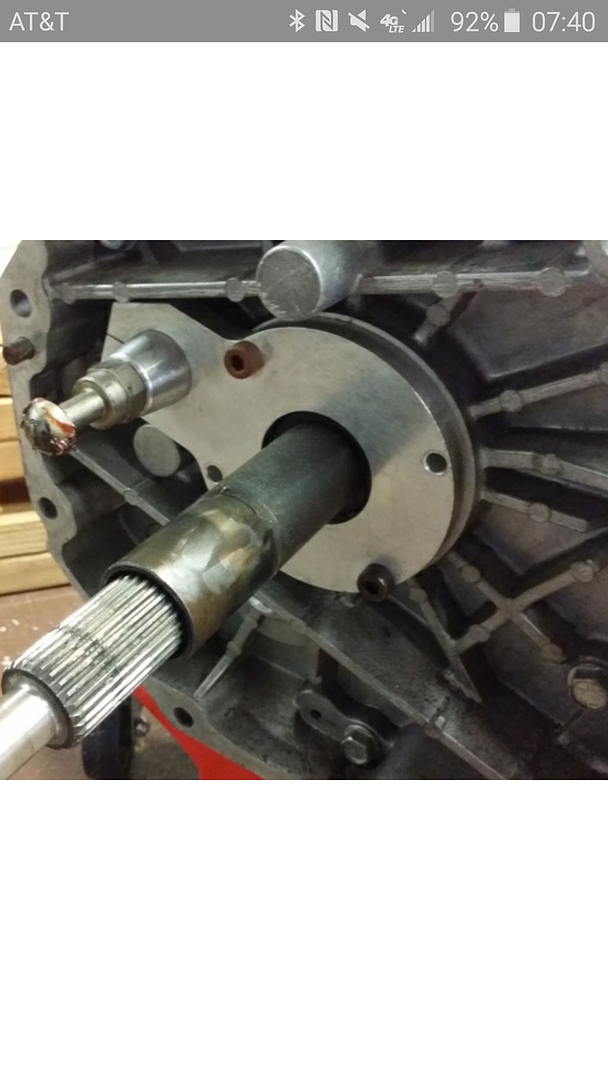

It boils down to, I need to move the threaded sleeve of the bearing away from the face of the trans about an inch but still give that sleeve something to push against.

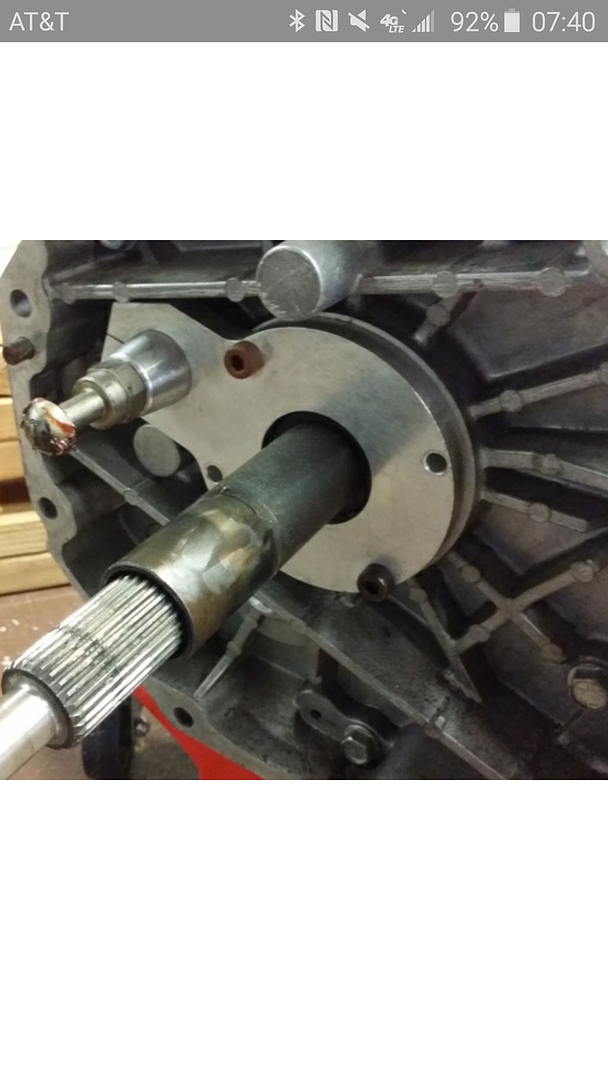

This picture shows the sleeve threaded all the way out.

My cable setup used this adjustable pivot ball bracket but I believe that the sleeve will fit inside the i.d. so it would be no help

Viper T56

McLeod hyd throwout bearing....fully threaded IN the bearing face is 1.725" from face of trans which is 1.3"+/- from the fingers

Custom twin disc.....fingers are 3.06" from face of trans.

The bearing gets .06" closer with every turn on the adapter sleeve. At my measurements it would take about 23 turns to give me the .100" - .150" gap.

It boils down to, I need to move the threaded sleeve of the bearing away from the face of the trans about an inch but still give that sleeve something to push against.

This picture shows the sleeve threaded all the way out.

My cable setup used this adjustable pivot ball bracket but I believe that the sleeve will fit inside the i.d. so it would be no help

Comment