Announcement

Collapse

No announcement yet.

Crank damage and rod bearings.

Collapse

X

-

take a fine file and clean up the dings, replace the bearings or, use them as is. smooth up those dings on the crank

. Make sure each rod will slide back and forth after it's torqued. You can buy plastiguage to check the clearances. those small scratches you see on the mains and likely all the rods are the result of working in your shop at home. It's not a clean area. all the surfaces catch things when it sits in the shop. Look at it with a magnifying glass. The bearing surfaces is designed to trap and contain a lot of trash. the oil filter will trap most of the crap in it when you put it together after the oil pressure flushes it out.

When you don't turn a crank, the new bearings conform to all those micro scratches in the old crank surface, some of that in the bearing comes from the old crank surface.Last edited by jyro; 12-26-2014, 12:55 AM.Don't worry about what you can't change.

Do the best you can with what you have.

Be honest, even if it hurts.

"Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy; Its inherent virtue is the equal sharing of misery" ... Winston Churchill

-

The crank was polished before I installed it. My thought was it was trash, micro fibers caught in between the surfaces.

The bearings only have hand turns on them, okay to use or should I replace?

It's going to be taking 150 hit of juice with a mild h/c/i 302, ~500whp

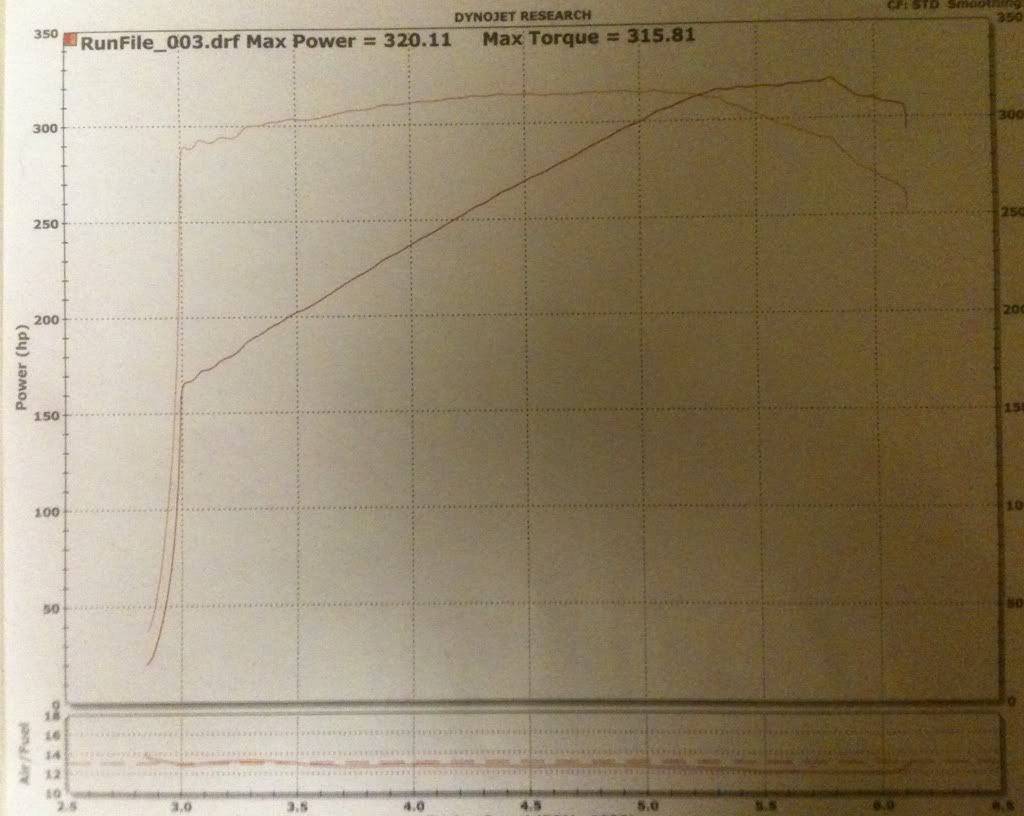

320rwhp. 7.67 @ 90mph 1.7 60'

DD: 2004 GMC Sierra VHO 6.0 LQ9 324whp 350wtrq

Comment

-

Yea, that crank looks "not to good". It looks like trash in assembly and turning the crank without oil pressure. Nicks in the crank are stress points and bad for the oil surface area between the crank and bearing.Originally posted by dcs13 View PostIf it were me, i'd send the crank for a polish and put new bearings. Couple of those gouges look bad. Use some fuel line pieces on your rod bolts next time to save damage.

If you find a way to keep the trash out without a surgery clean room let me know.

I don't know how many times I think I got a "Clean Room" and still find signs of trash in the motor. Might grind the one journal undersize to get the nicks out of it. As said put fuel line on the rod bolts in assembly to prevent the damage to the crank.

Have you had any issues with your Brodex heads ??

Comment

-

Bearings look pretty good to me from the pics, that cloudy white stuff comes off VERY easy, IE checking the bearing ID with a bore gauge will take that stuff right off.

I would wipe the crank down and take another pic, it doesn't look great, a little trash, and those gouges are from assy/disassy.Interested in being a VIP member and donating to the site? Click here http://dfwmustangs.net/forums/payments.php

Comment

-

Originally posted by Kart21 View PostYea, that crank looks "not to good". It looks like trash in assembly and turning the crank without oil pressure. Nicks in the crank are stress points and bad for the oil surface area between the crank and bearing.

If you find a way to keep the trash out without a surgery clean room let me know.

I don't know how many times I think I got a "Clean Room" and still find signs of trash in the motor. Might grind the one journal undersize to get the nicks out of it. As said put fuel line on the rod bolts in assembly to prevent the damage to the crank.

Have you had any issues with your Brodex heads ??

Thanks for the tips!

The only issue I've had is the valve cover bolts go into the exhaust port on cylinder 8, it blew the Bolt out and caused an exhaust leak, fixed it with by putting heli coils in every hole, valve cover, intake and exhaust.

Other then that Ive been extremely impressed by they way they performed, I picked up 90whp over the stock top end, all before 6,000 rpm. Baby cam too 218/228, theyre 171cc intake runners that have been worked a tad bit.

I would put them up against some afr 165sLast edited by 91CoupeMike; 12-26-2014, 09:42 AM.

320rwhp. 7.67 @ 90mph 1.7 60'

DD: 2004 GMC Sierra VHO 6.0 LQ9 324whp 350wtrq

Comment

Comment