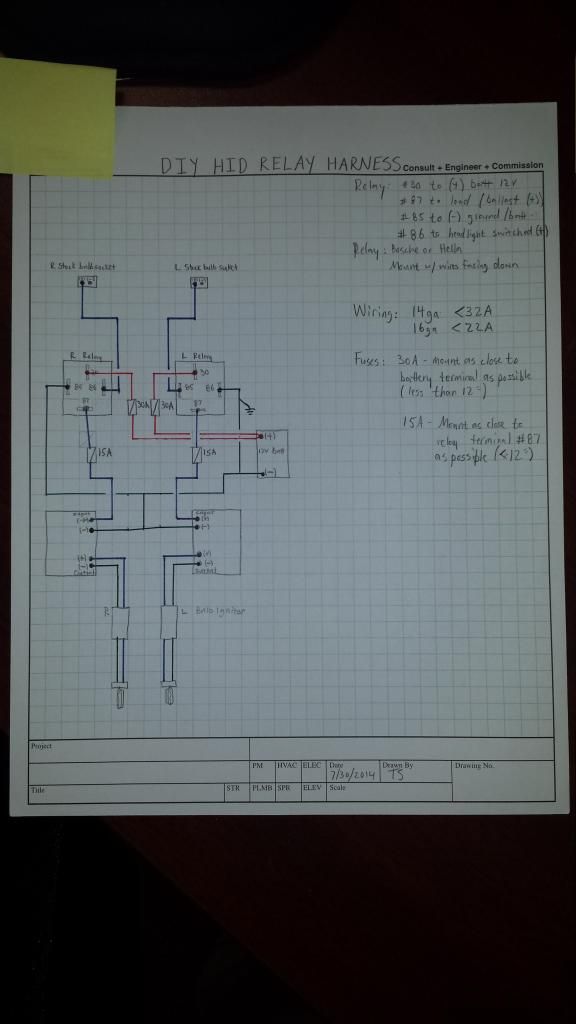

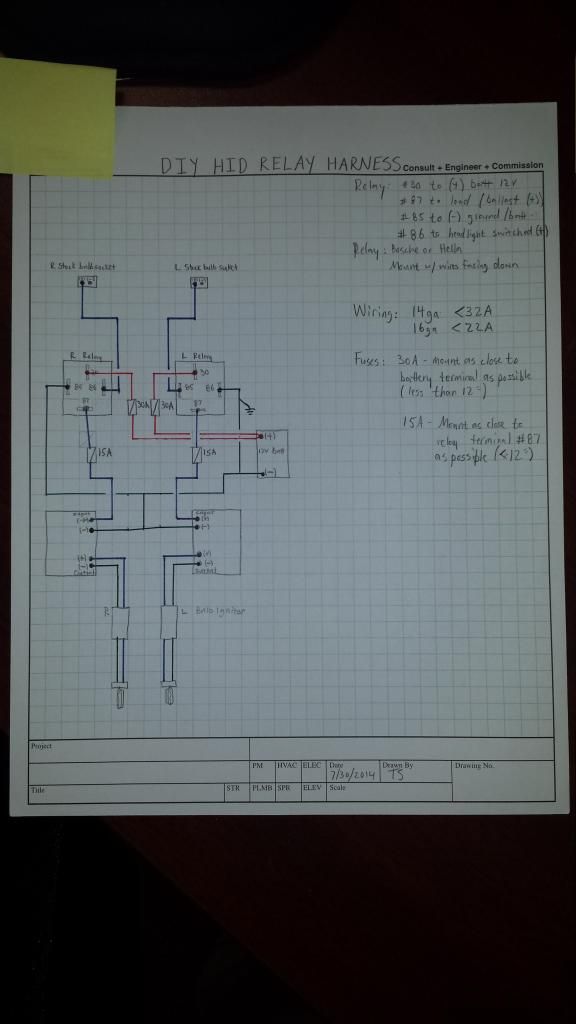

I ordered a replacement ddm kit after my first kit if 3 years failed. The new kit (same wattage) flickers and I don't want to wait for their dinky harness to ship from China so I'm gonna wire one up this weekend. Im going to use my old kit's connectors to build a true pnp dual relay harness and tidy it all up behind the bumper support. Does this look correct? All input is appreciated!

Comment