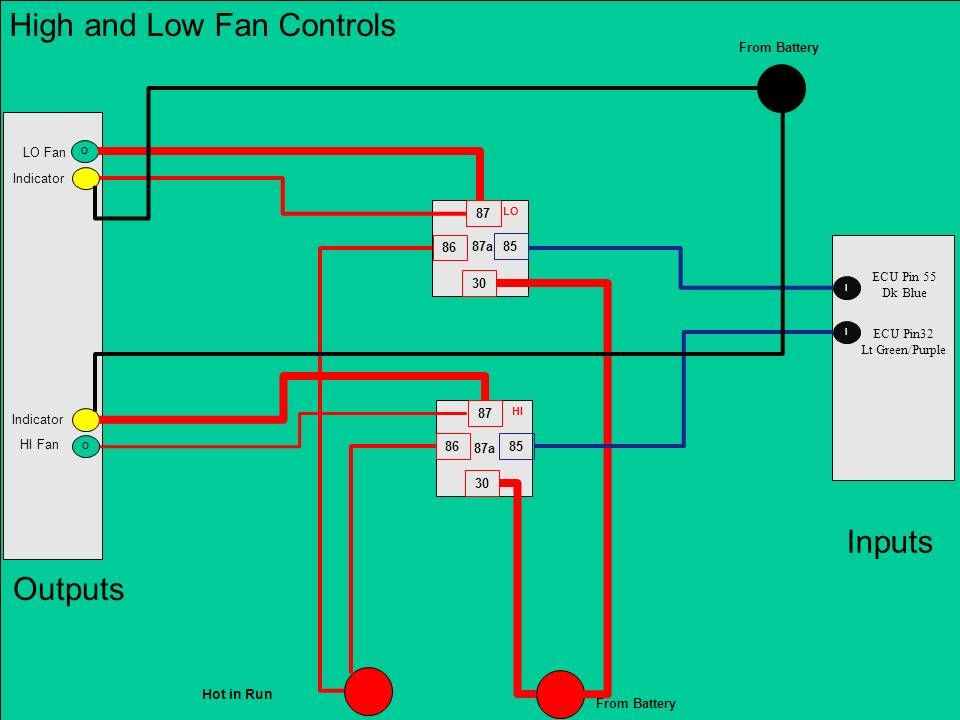

Do you prefer to Ground to turn on or Power to turn on?

Ground to turn on:

85 - Switch (switched to ground)

30 - Constant or switched 12v power (fused)

86 - Constant or switched 12v powr (fused)

87 - Device (grounded) - On when switched on

87a - Device (grounded) - On when switched off

Power to turn on:

85 - Switch (switched to 12v (fused))

30 - Constant or switched 12v (fused)

86 - Grounded

87 - Device (grounded) - On when switched on

87a - Device (grounded) - On when switched off

I am leaning to Power to turn on. Can I get your thoughts? Is one safer than the other?

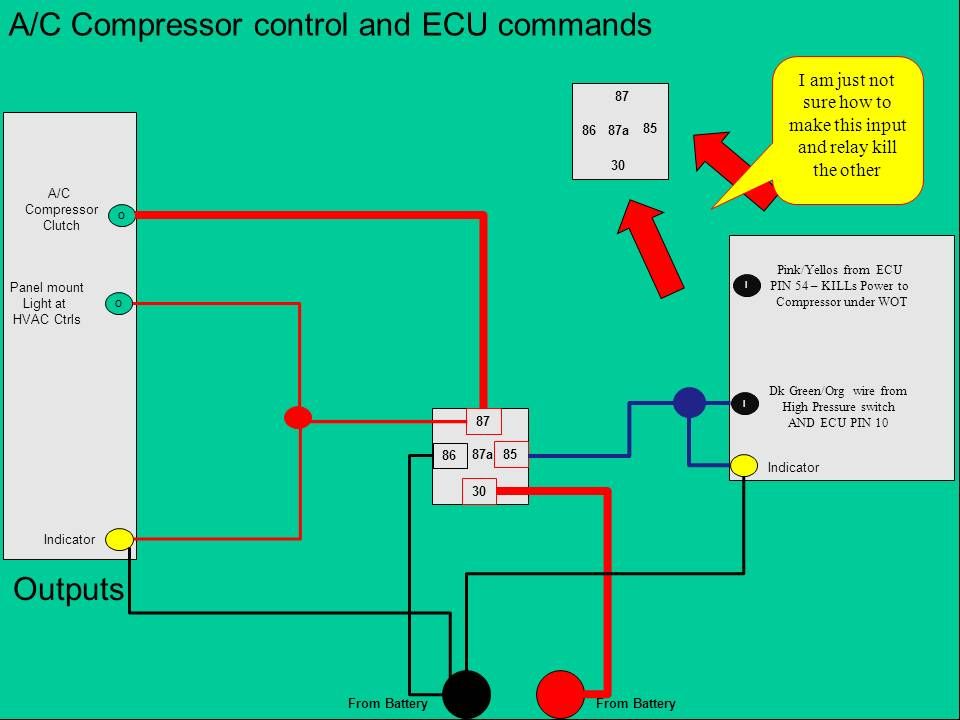

Ground to turn on:

85 - Switch (switched to ground)

30 - Constant or switched 12v power (fused)

86 - Constant or switched 12v powr (fused)

87 - Device (grounded) - On when switched on

87a - Device (grounded) - On when switched off

Power to turn on:

85 - Switch (switched to 12v (fused))

30 - Constant or switched 12v (fused)

86 - Grounded

87 - Device (grounded) - On when switched on

87a - Device (grounded) - On when switched off

I am leaning to Power to turn on. Can I get your thoughts? Is one safer than the other?

Comment