So in order to bring my old thread back to life like old Lazarus I wanted to add something about flushing ac systems due to an asshat at Oriellys arguing with me about it.

There's different types of flush to use in an ac system. Im only going to talk about to 2 main ones youll see at a parts store. There's an oil type and a solvent.

Castrol came out with this light oil flush abomination and it's absolutely snake oil junk. Youre supposed to use a closed loop flushing machine with it. Think about how this junk is supposed to work. You're using an oil to push more oil and debris out of the system. It's like using a lower viscosity oil to flush your engine. The oil doesnt clean jack crap. I got duped by the 50y/o assistant manager retard into using this junk once. I stuck it in the flush can and proceeded to spray this stuff through each metal componet. Then I flushed everything with air. Charged the system in this big rig and started it for testing. Everything worked fine for about 4 par sec's then a massive BOOM. Blew the high pressure line apart and shot oil over everything. When you're spraying oil into a a condenser or evaporator all that oil just sits in the bottom until the refrigerant blows it through and locks shit up. So a long story short dont use it and make sure the flush you use is solvent.

Now there's a lot of controversy over how or when to flush an a/c system. Ill tell you what I do and you can do your own research if you want. There's only a few different cases when I flush a system. After a compressor goes bad, the system has been open for a while, or converting a system to r134a. An ac system doesnt need to be flushed because of any leak unless a line is completely un-hooked for a while and not plugged. Or if this system had 0psi in it. If there's any pressure left in the system then outside air isnt going to get in it

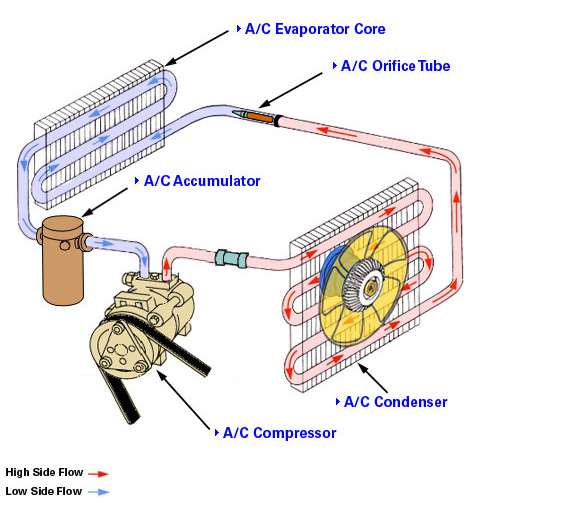

If the compressor grenaded internally Ill flush the metal lines, and the evaporator. Ill change the condenser, rubber lines, o-tube or expansion valve, accumulator/receiver dryer, and obviously the compressor. When the compressor goes bad it either sends tiny metal shavings or melted teflon(black death) into the system. The shavings will impregnate the rubber hoses, get stuck in the desiccant in the accumulator/dryer, and plug up the o-tube/expansion valve so replace them. The only reason I dont replace the evaporator is due to the high amount of labor. Iv started replacing the condensers because the newer system are mostly a parallel flow or serpentine style that has tiny passages through it so the shavings get clogged into the passages at about 200-250psi. Reverse flushing with shop air(90-110psi) isnt going to get it out.

So if you take your vehicle to a shop and they tell you that you need a flush due to a leak tell them to take a hike. And if a parts store button pusher hands you anything that says "A/C flush oil" through it at him.

There's different types of flush to use in an ac system. Im only going to talk about to 2 main ones youll see at a parts store. There's an oil type and a solvent.

Castrol came out with this light oil flush abomination and it's absolutely snake oil junk. Youre supposed to use a closed loop flushing machine with it. Think about how this junk is supposed to work. You're using an oil to push more oil and debris out of the system. It's like using a lower viscosity oil to flush your engine. The oil doesnt clean jack crap. I got duped by the 50y/o assistant manager retard into using this junk once. I stuck it in the flush can and proceeded to spray this stuff through each metal componet. Then I flushed everything with air. Charged the system in this big rig and started it for testing. Everything worked fine for about 4 par sec's then a massive BOOM. Blew the high pressure line apart and shot oil over everything. When you're spraying oil into a a condenser or evaporator all that oil just sits in the bottom until the refrigerant blows it through and locks shit up. So a long story short dont use it and make sure the flush you use is solvent.

Now there's a lot of controversy over how or when to flush an a/c system. Ill tell you what I do and you can do your own research if you want. There's only a few different cases when I flush a system. After a compressor goes bad, the system has been open for a while, or converting a system to r134a. An ac system doesnt need to be flushed because of any leak unless a line is completely un-hooked for a while and not plugged. Or if this system had 0psi in it. If there's any pressure left in the system then outside air isnt going to get in it

If the compressor grenaded internally Ill flush the metal lines, and the evaporator. Ill change the condenser, rubber lines, o-tube or expansion valve, accumulator/receiver dryer, and obviously the compressor. When the compressor goes bad it either sends tiny metal shavings or melted teflon(black death) into the system. The shavings will impregnate the rubber hoses, get stuck in the desiccant in the accumulator/dryer, and plug up the o-tube/expansion valve so replace them. The only reason I dont replace the evaporator is due to the high amount of labor. Iv started replacing the condensers because the newer system are mostly a parallel flow or serpentine style that has tiny passages through it so the shavings get clogged into the passages at about 200-250psi. Reverse flushing with shop air(90-110psi) isnt going to get it out.

So if you take your vehicle to a shop and they tell you that you need a flush due to a leak tell them to take a hike. And if a parts store button pusher hands you anything that says "A/C flush oil" through it at him.

Comment