Originally posted by dville_gt

View Post

Announcement

Collapse

No announcement yet.

LS-coupe cooling saga continues :(

Collapse

X

-

running an external trans coolerOriginally posted by forbes View Posti don't know your whole setup, but just throwing this out. i know your an automatic with a pretty high stall. are you running a trans cooler or only into the tank on the radiator? maybe your trans fluid is contributing to the heat build up?

SBC's regulated temp by a thermostat that didn't let coolant out of the engine and LSx engines regulate temp by a thermostat that doesn't let coolant in to the engine. So the upper hose is taking hot coolant from the motor to the radiator and the lower is returning the cooled coolant to the thermostat/motor.Originally posted by Strychnine View PostMy opinion...

I would run the sensor in the manifold near the t-stat housing where the coolant from all passages is mixing again.

The engine is always going to have localized hot spots. What you're looking for is the average temp, or what the radiator is going to be seeing. That's what the complete system is designed for.

Your overall cooling system health is gauged by heat rejeciton capability of your radiator... or the differential between radiator inlet and outlet (or radiator inlet to ambient), not the differential between one single point and ambient.

I know some guys will say this is "cheating the system" because you're just changing your measurement, but you have to think about what the system was designed for. Overall (average) engine heat rejection.

FWIW, our coolant temp sensors (that feed the ECM) are very close to the thermostat housing and when I do full load cooling tests my jacket water thermocouples are always in the radiator inlet tube.

I could pretty easily put the ECT sensor in the water pump housing on the out let to the radiator side. This should be the hottest point since it would be the coolant that is on it's way to get cooled, or would it be better to put it on the already cooled side of things?

Comment

-

I would still put it as close as possible to where coolant exits the engine. That's the temperature that you will need to monitor as that is what the radiator will be working with.

The fact that the t-stat is down low is really only a factor when it is warming up or modulating (still nowhere near max cooling capacity). Once you're at operating temp (or higher like you're seeing now) when your t-stat is wide open you're going to want that rad inlet temp.

Comment

-

Not discounting your advice by any means, but many of the tuning folks suggest not even moving the factory ect to the opposite cylinder, much less to a totally different part of the cooling system. Since the car is right at the threshold of staying cool enough I am tempted to just throw in 100% water with some type of anti corrosion/pump lube for the summer months and be done with it. If it'll buy me 10 degree's I think I'd be okay, car does fine in 95* temps, just can't manage to stay at or below 220 when the temps go too much higher.

Apparently it's not all too strange to see these motors in the 230-240 range in 100+ heat. Seems high to me, but then again I want 180* and it never move.

What do you think?

Comment

-

Originally posted by dville_gt View PostNot discounting your advice by any means, but many of the tuning folks suggest not even moving the factory ect to the opposite cylinder, much less to a totally different part of the cooling system. Since the car is right at the threshold of staying cool enough I am tempted to just throw in 100% water with some type of anti corrosion/pump lube for the summer months and be done with it. If it'll buy me 10 degree's I think I'd be okay, car does fine in 95* temps, just can't manage to stay at or below 220 when the temps go too much higher.

This is part disclaimer and part trying to help, lol. I haven't had a project car in a while so my sense of personal attachment to things like this is low. I won't be the least bit offended if tell me to DIAF

My mindset might be a bit different. I'm coming from a world where engines (that someone else paid for) have to be able to operate at 100% throttle, 100% load for hours on end, right up to the limiting ambient temp design limit.

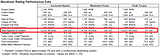

On an engine datasheet no one publishes any sort of temperatures. There is only a heat rejection, measured in BTU/min. That is a "system wide" average and it is the only value related to engine heat that is used to size a radiator. The term 'heat rejection' is very telling here... heat goes from the cylinder through the walls, into the coolant, and out of the engine to the radiator. The heat (that average number) is rejected at the engine outlet.

[thumbnail]

And really, if there's a limit and you're 20*F below it or just 1*F below it... you're still below it. If running straight water for the next couple weeks keeps everything in line then do it.

I don't want to sound like I'm discounting anything the LSx pros do, by any means. I'm speaking more from an general engine design and integration standpoint... and I'm not GM so I don't know what their logic is on certain stuff.

I know that we put coolant temp sensors, both factory installed (to feed the ECM) and OEM installed (for backup gauges), as close to the t-stat housing as possible. Unless someone is burning up pistons/valves/etc or something (like Forrest had some engines doing a few yrs ago) I don't care about coolant temp at cyl1 vs cyl6 or any other single spot in there.

I'm not sure why they say to never move a sensor. I know that it's the standard spot for everyone and it helps keep a nice baseline for comparison across the board, but in my mind measuring anywhere other than the engine outlet is like trying to figure out the average height of the people in a company by only surveying the accounting department instead of standing at the front door and getting everyone.

[thumbnail]

Just for fun, take your IR temp gun and shoot your radiator inlet tube in a few different places and compare that average to your gauge reading and see what the difference is.

What is GM's coolant temp threshold for the idiot light on the dash?

All of this is to say that IMO you could be worrying about nothing. If you have never boiled over you really don't know how close you are to the system limit.

I'm with you. In my project cars 180-200*F is ideal for me if possible, mostly for the peace of mind. When it's someone else's money... 225*F.Originally posted by dville_gt View PostApparently it's not all too strange to see these motors in the 230-240 range in 100+ heat. Seems high to me, but then again I want 180* and it never move.

What do you think?

This could all be worthless though... the problem could be somewhere totally different Last edited by Strychnine; 08-16-2011, 09:59 AM.

Last edited by Strychnine; 08-16-2011, 09:59 AM.

Comment

-

I don't know what temp the "check gauges" light would come on in a factory cluster. I do know that the lsx f-bodies gauge reads 210 all the time (between 180-230* at the ect sensor). Only after 230 will the factory gauge move from 210* so they obviously don't feel like 230 is "too hot".Originally posted by Strychnine View PostWhat is GM's coolant temp threshold for the idiot light on the dash?

All of this is to say that IMO you could be worrying about nothing. If you have never boiled over you really don't know how close you are to the system limit.

I'm with you. In my project cars 180-200*F is ideal for me if possible, mostly for the peace of mind. When it's someone else's money... 225*F.

This could all be worthless though... the problem could be somewhere totally different

I've def. never boiled over, never smelled the coolant smell, and the car does fine as long as the temp stays below 100*. If running straight distilled for the hot summer months is what it takes then that is a cheap and easy fix. If it'll just stay below 225* a/c on, 105* @ idle and @ 3.2k rpm @ 65-70mph then I will be happy.

Comment

-

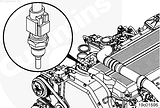

I find that last part hard to believe if it's that close to the header. That must be one insulated ass sensor to not get heat soak.Originally posted by dville_gt View Post

Seemed likely to me (there is a picture a page or two back) since both sensors are literally a few mm away from the header flange (that is over 500*), but this idea was axed since the sensors should only be reading the coolant and should be unaffected by the massive heat monster that is so close to them.

.Vortex rear stand $75

8.8 410s. $50

**SKAGG NASTY**

My goal in life is to not arrive at the grave in a well preserved body.

but rather to skid in sideways, totally worn out, shouting "holy shit!!!.. what a ride!"

1990 Foxbody GT for that ass

11 4 door

4 door

13 FX2 White 5.0

Comment

-

Its not an LSx, but a team I race with was fighting a problem in a thundertird with a 4.6, and finally found that those cars tend to run 220+ "normally" and thathey really didn't have anything to worry about.

I'm like you, I like my temp between 180 and 210 or so."If I asked people what they wanted, they would have said faster horses." - Henry Ford

Comment

-

-

I guarantee that thing is get heat soak. The coolant passing over the sensor itself is probably cooling it down. LolOriginally posted by dville_gt View Post

not sure it could physically be any closer to the header flange!Vortex rear stand $75

8.8 410s. $50

**SKAGG NASTY**

My goal in life is to not arrive at the grave in a well preserved body.

but rather to skid in sideways, totally worn out, shouting "holy shit!!!.. what a ride!"

1990 Foxbody GT for that ass

11 4 door

4 door

13 FX2 White 5.0

Comment

-

liquid temps will affect the sensor reading more than ambient air would. The sensor is designed to be submerged to get a correct reading, they respond to temp changes slowly when exposed to air and not liquid. This is the reason that by the time you realize the engine temp has gone up from a loss of coolant it is usually to late. Especially if the sensor is mounted higher up in the cooling system.

As far as the a\c goes, That compressor for the escalade and the camaro should be pretty well the same part. The condenser size will likely have little effect on the system (from an escalade to camaro standpoint.

Your high side pressure is the one to be concerned with. People put a lot of faith in a low side reading. The low side pressure is important in the "cold" part of the a\c, but the high and low side pressures together are need to help correctly determine if there is a problem. If you're high side pressure is 400psi for instance, then the condenser will be generating more heat that if it is at 275 psi. Make sure your heater core bypass hose doesn't kink, a flow restriction there will sometimes affect the cooling system performance.

Comment

-

On this note, the camaro and escalades don't share compressors. There is also the option of rear air in the escalade.Originally posted by shumpertdavid View Postliquid temps will affect the sensor reading more than ambient air would. The sensor is designed to be submerged to get a correct reading, they respond to temp changes slowly when exposed to air and not liquid. This is the reason that by the time you realize the engine temp has gone up from a loss of coolant it is usually to late. Especially if the sensor is mounted higher up in the cooling system.

As far as the a\c goes, That compressor for the escalade and the camaro should be pretty well the same part. The condenser size will likely have little effect on the system (from an escalade to camaro standpoint.

Your high side pressure is the one to be concerned with. People put a lot of faith in a low side reading. The low side pressure is important in the "cold" part of the a\c, but the high and low side pressures together are need to help correctly determine if there is a problem. If you're high side pressure is 400psi for instance, then the condenser will be generating more heat that if it is at 275 psi. Make sure your heater core bypass hose doesn't kink, a flow restriction there will sometimes affect the cooling system performance.

Is it possible that that compressor is pputting out too much volume, creating excessive heat in the condenser?"If I asked people what they wanted, they would have said faster horses." - Henry Ford

Comment

-

High side pressure was was about 300psi if I recall correctly. The bypass hose is a preformed hose and is designed for that exact bend. No kinks. The condenser never seems to be real hot to the touch.Originally posted by shumpertdavid View Postliquid temps will affect the sensor reading more than ambient air would. The sensor is designed to be submerged to get a correct reading, they respond to temp changes slowly when exposed to air and not liquid. This is the reason that by the time you realize the engine temp has gone up from a loss of coolant it is usually to late. Especially if the sensor is mounted higher up in the cooling system.

As far as the a\c goes, That compressor for the escalade and the camaro should be pretty well the same part. The condenser size will likely have little effect on the system (from an escalade to camaro standpoint.

Your high side pressure is the one to be concerned with. People put a lot of faith in a low side reading. The low side pressure is important in the "cold" part of the a\c, but the high and low side pressures together are need to help correctly determine if there is a problem. If you're high side pressure is 400psi for instance, then the condenser will be generating more heat that if it is at 275 psi. Make sure your heater core bypass hose doesn't kink, a flow restriction there will sometimes affect the cooling system performance.

Comment

-

the denso 10S17F is used in the cts, gm trucks/suv's, and i think the gto as well. seems like it'd have to have to have the ability to work with different sized condensers if they use it in so many applications. the denso 10S17F is for the non-rear a/c vehicles.Originally posted by Baron View PostOn this note, the camaro and escalades don't share compressors. There is also the option of rear air in the escalade.

Is it possible that that compressor is pputting out too much volume, creating excessive heat in the condenser?

Comment

Comment