Originally posted by Sleeper

View Post

Announcement

Collapse

No announcement yet.

What I have been working on

Collapse

X

-

You got me, the only bottom tap I could find in 3/8" NPT was $80 on amazon."When the people find that they can vote themselves money, that will herald the end of the republic." -Benjamin Franklin

"A democracy will continue to exist up until the time that voters discover that they can vote themselves generous gifts from the public treasury." -Alexander Fraser Tytler

Comment

-

I'm serious though! I currently have five trucks I'm working on, and I'll get hung up on getting ONE particular thing accomplished, and once I'm stuck on that, I just shut down on any sort of multi-tasking... OCD

but then at the point where progress is actually getting made, I ADD on over to something completely different and then get hung up on it LOL

Comment

-

No luck on a bottoming tap. I have a regular one that's $8.49.Originally posted by kbscobravert View PostLet me know, otherwise I already have a few weld bungs coming and it ain't nothing for me to get them welded in."It is in truth not for glory, nor riches, nor honours that we are fighting, but for freedom - for that alone, which no honest man gives up but with life itself."

Comment

-

Well fuck me. If it isn't one thing it is 10 others.

Crank trigger kit looks good and seems like it would work like a champ on a fox body but that is where the joy ends.

94/95 crank pulley has an offset like a wheel. A standard 302 doesn't. So with the wheel setting against the balancer the the pulley lacks 0.290" from the hub face sitting against anything.

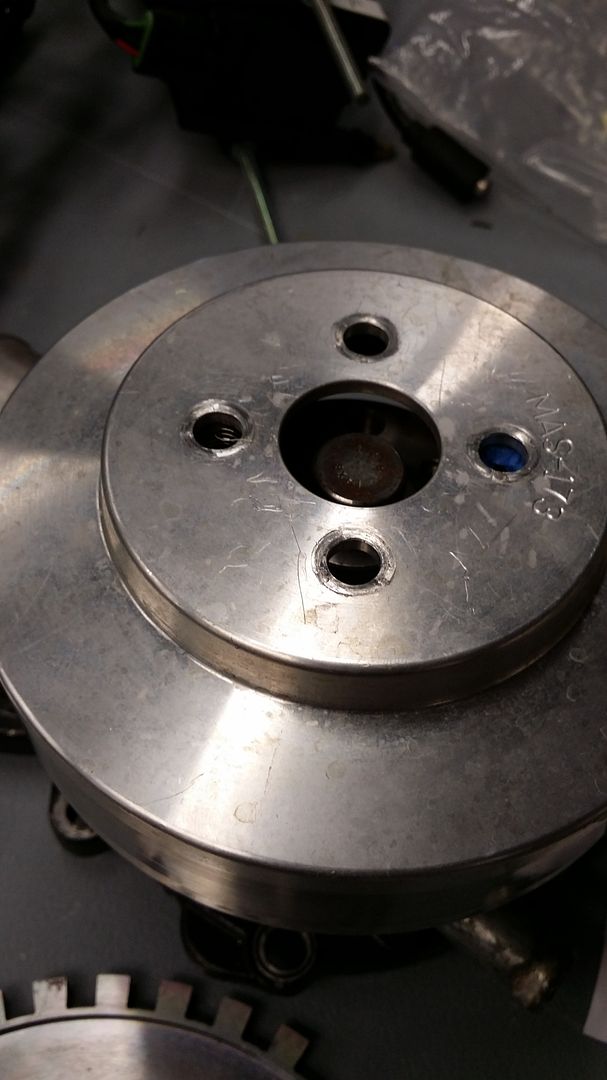

(back)

Crank pulley laying on the wheel. You can see how this would need a spacer.

94/95 water pump is further to the rear and thus so is the pulley. Well, the pulley hits the trigger wheel. Great! So playing with washers, it took 0.900" of a spacer to get the water pump pulley in front of the trigger wheel. That being the greatest distance needed, the crank pulley has to come forward that MINUS the 0.290" backspacing.

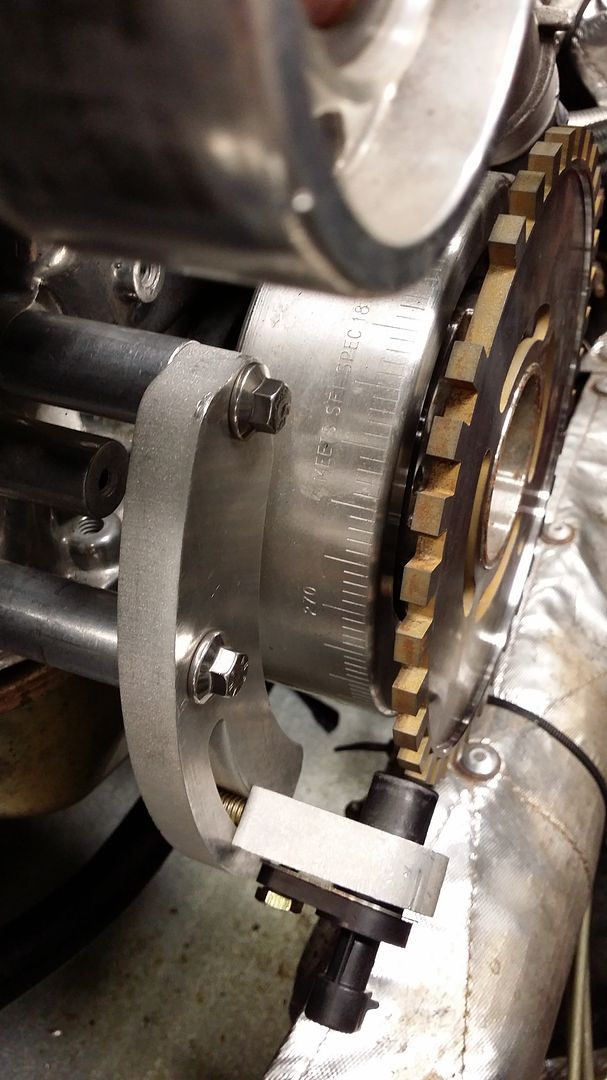

How far up the pulley has to sit to clear the wheel below it

Wheel resting on the balancer

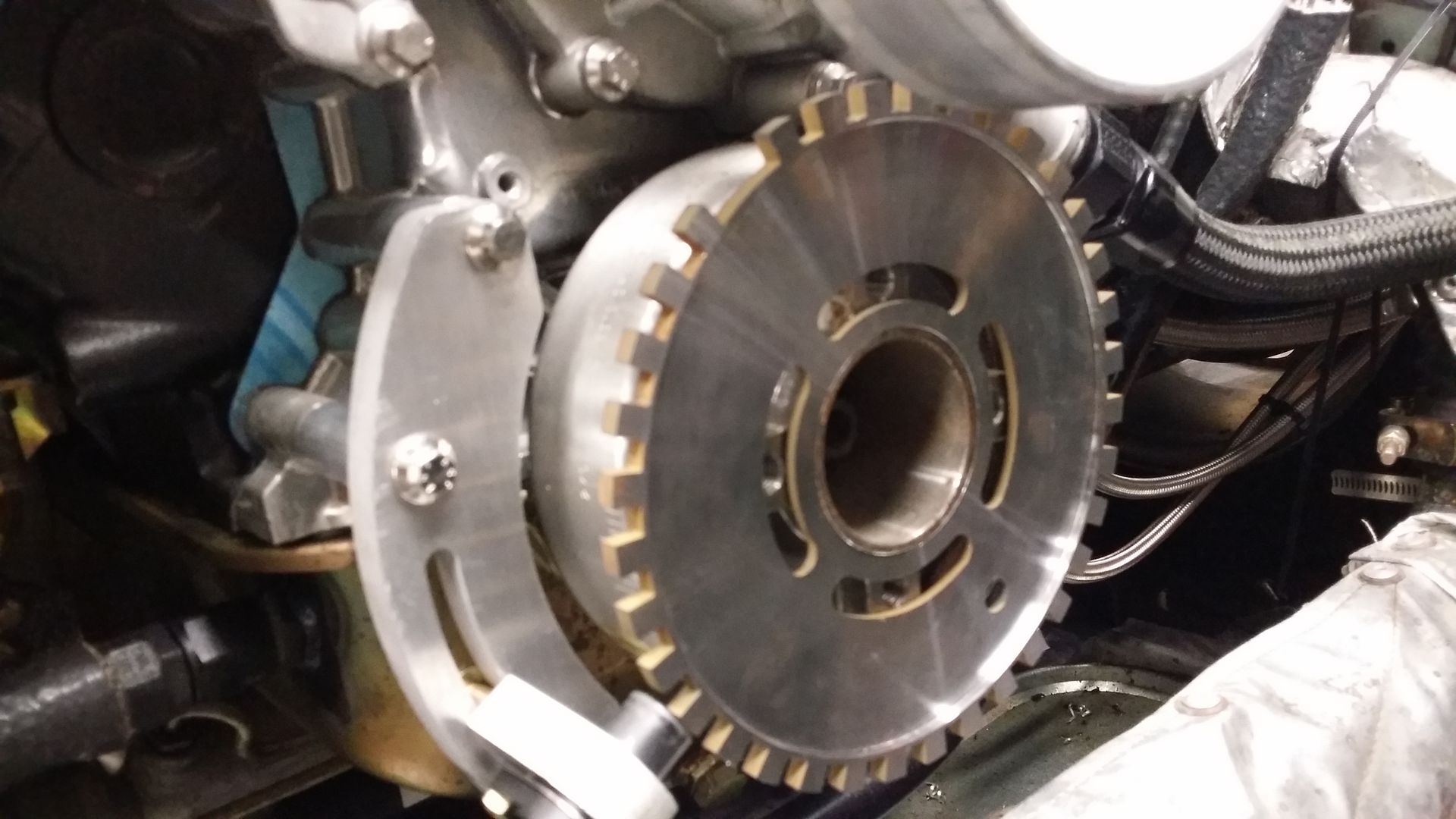

You can see the water pump pulley trying to occupy the same space.

The easy part will be the alternator bracket and power steering bracket that will need to come forward 0.900" to line up with the water pump pulley and crank. But then I have to find bolts (not THAT big of a deal, maybe) and as long as the bracket (bolt) clears the water pump heater inlet hose we will be fine.

If I had a lathe and some 6" aluminum stock and a mill maybe, this would be pretty easy to fix.Fuck you. We're going to Costco.

Comment

-

So here is my plan. I found a 1.00" fan spacer that we can chuck up and machine down to space the water pump instead. Comes with bolt holes and bolts, also pilot holes that should already match.

Ordered a FRPP crank spacer that is 0.909" and again bolt holes drilled and pilot shoulders already there. Just have to tune it to line up with the water pump.

Fuck you. We're going to Costco.

Comment

-

I hit up the hardware store and got the new bolts. Now just waiting on the spacers to show up.

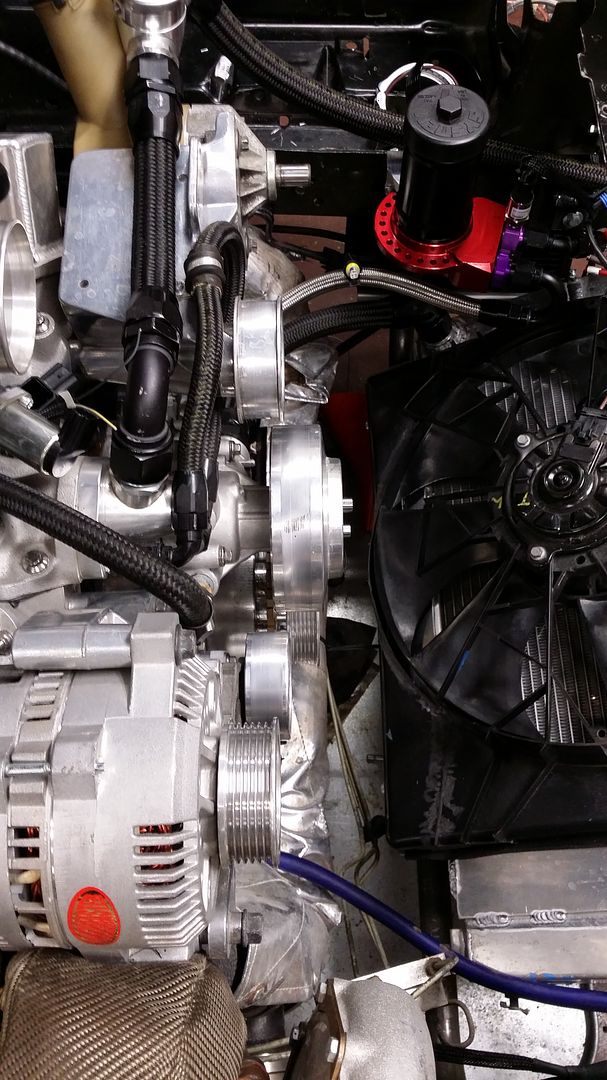

Here is the water pump pulley spaced out far enough to clear the trigger wheel. Everything else is going to come forward too.

When the alternator bracket moves forward the bolt will hit the heater hose fitting. I am going to pull the steel tube and tap the case down as far as I can then use a low profile 90* adapter to clear....hopefully. If not, I have a few other ideas but they require adding material and lot of cussing.

Fuck you. We're going to Costco.

Fuck you. We're going to Costco.

Comment

-

Oh! I have the adjustable rod from that kit, Not 100% sure I know where the tirangle bracket might be, but it's likely still around.Originally posted by Sleeper View Postyou might be able to convert one of those march alt brackets easy enough. I forget exactly how they mount tho. Its only been 7 years or so since i did one."If I asked people what they wanted, they would have said faster horses." - Henry Ford

Comment

-

Sneak peek while I make a run for food to celebrate. 4" down pipe ready to be tack welded, test fit again and final welding.

Last edited by KBScobravert; 10-13-2014, 03:09 PM.Fuck you. We're going to Costco.

Last edited by KBScobravert; 10-13-2014, 03:09 PM.Fuck you. We're going to Costco.

Comment

Comment