I like the bolts. What is preventing it from sitting more flush with the hood surface?

Announcement

Collapse

No announcement yet.

What I have been working on

Collapse

X

-

Thanks. I am still trying to keep very subtle "racecar" mods to the outside.Originally posted by LaserSVT View PostThe bolted down look is very racecar. Gives it a more purposeful and menacing look.

I think it would look badass completely flush/recessed like the original GT500s but I think the cost of doing it would kill me. If I had a spare hood and lots of time on my hand, I might give it a go. At the same time I would cut a stocker and put a 1.5" rise in the back and close in the ports in the back.Originally posted by Rick Modena View PostI think it looks good like that. If you wanted the flush factory look, you could use some body adhesive and go up from underneath and use mairne tec, plastic filler, but of course that's time consuming and I'm not sure if you have the room for that.

Actually, the bottom side of the vent is rounded giving it the <1/16" lip. Without a very careful plainer I really don't want to try it. I would be afraid of changing the outside edge's contour.Originally posted by Pokulski-Blatz View PostThe hood surface.Fuck you. We're going to Costco.

Comment

-

Sadly I didn't get done as much as I wanted to this last trip home. The radiator is still not mounted, the old exhaust is out but there is nothing even mocked up to replace it, the old DP is out but it is the same - nothing mocked up yet, the E85 is finally out of the tank (thanks David) and the fuel lines are out - just need to drop the tank and start cleaning up the underside of the car for paint, the air/water got mocked up and I am happy with my efforts - now to get it built. Outside of that, the dash and interior didn't get touched, the battery cable didn't get ran and the Holley stuff is still just unboxed.Fuck you. We're going to Costco.

Comment

-

Got a great amount of work done this trip.

Stripped the car down. Exhaust out. Fuel tank and all fuel lines out. Crankcase evac system completely pulled out. Interior (dash, seats, console, carpet) out. Old EFI harness and all associated wiring out.

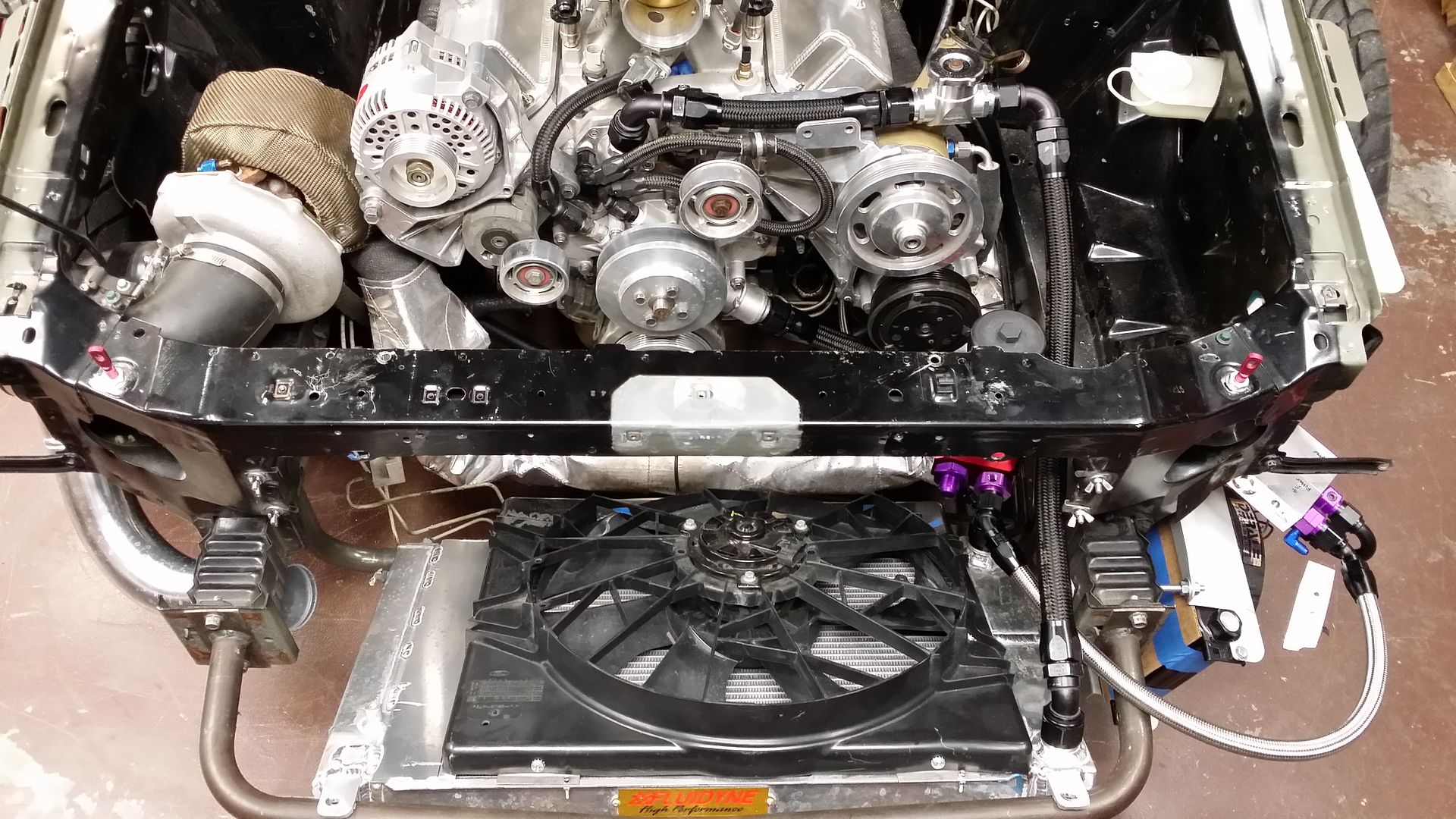

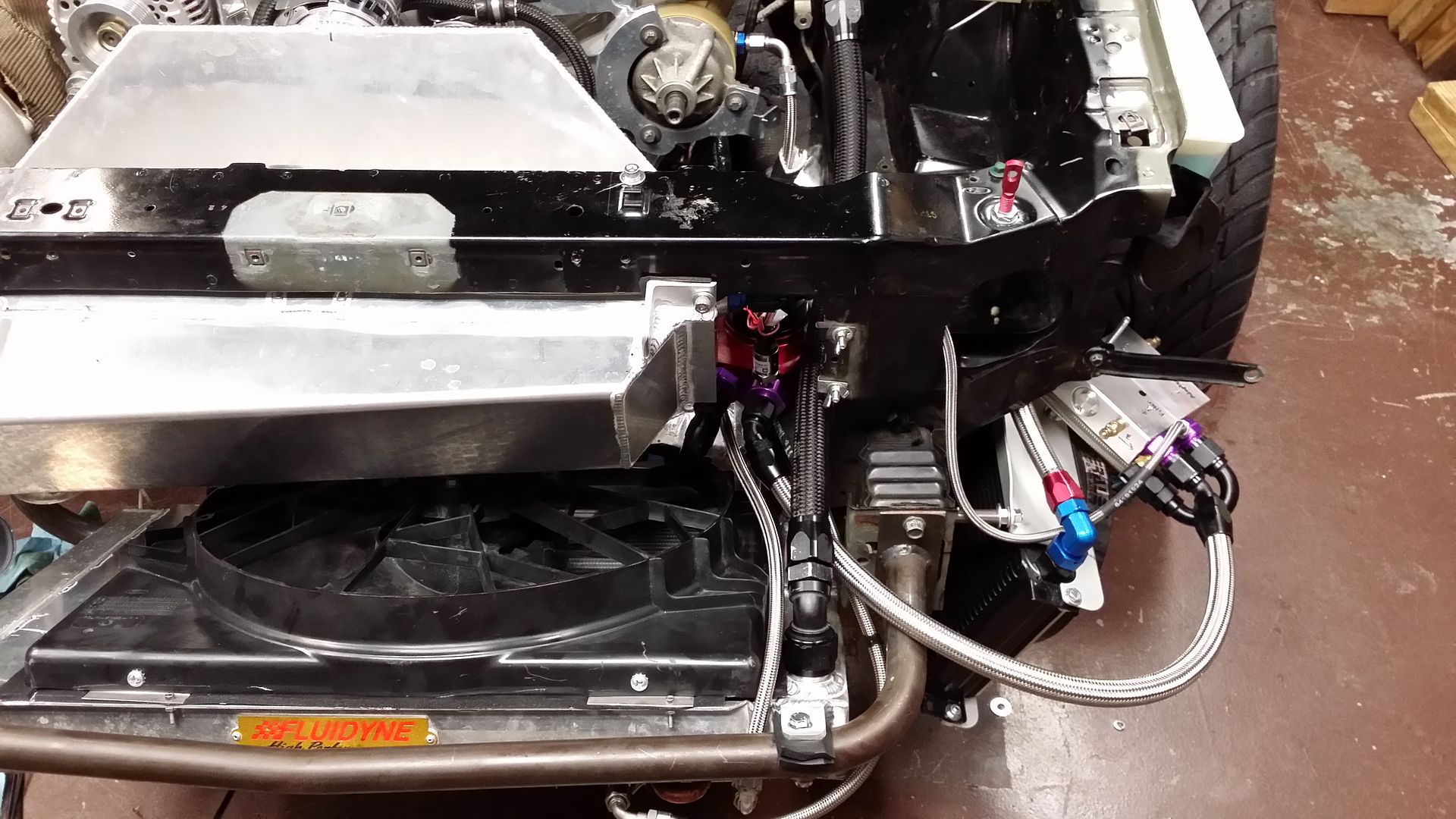

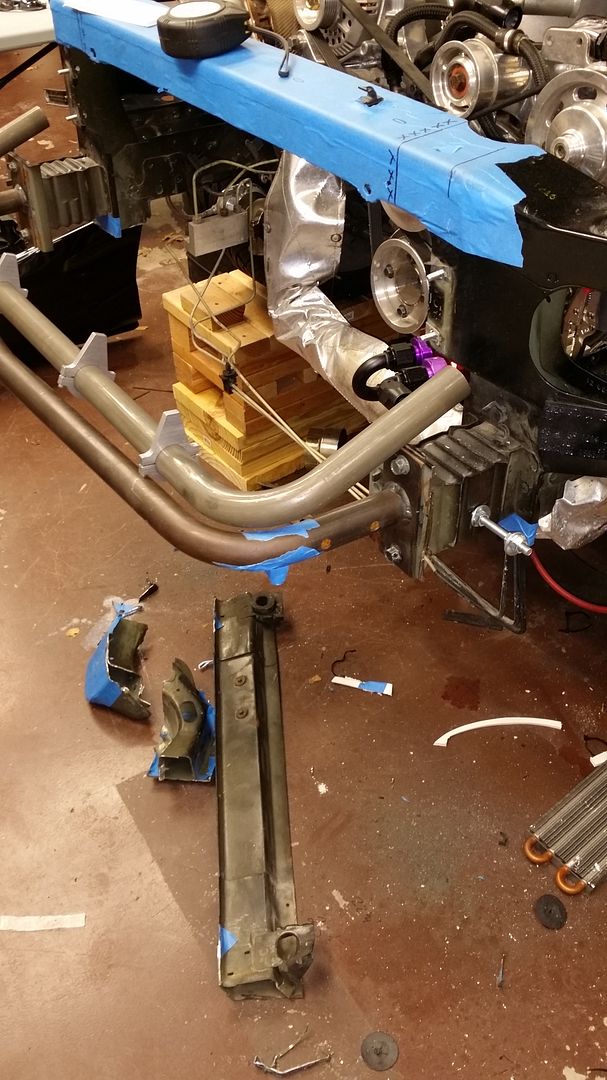

Sent 4 miles down the road to Matt's shop. He finished up the lower core support by welding in the new tubular one. He modified the radiator and mounted it and the fan. Mounted the intercooler and built the charge pipes.

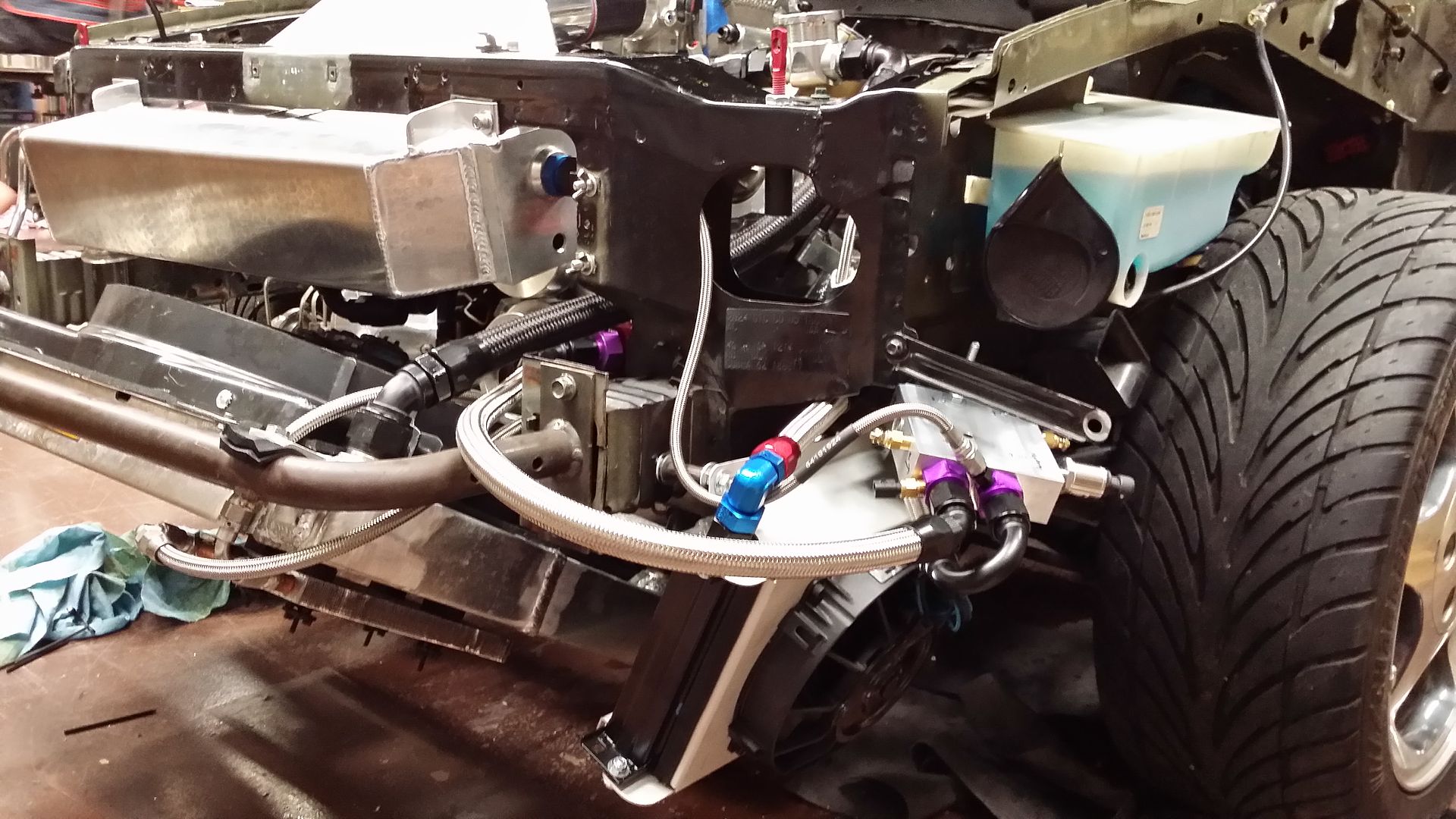

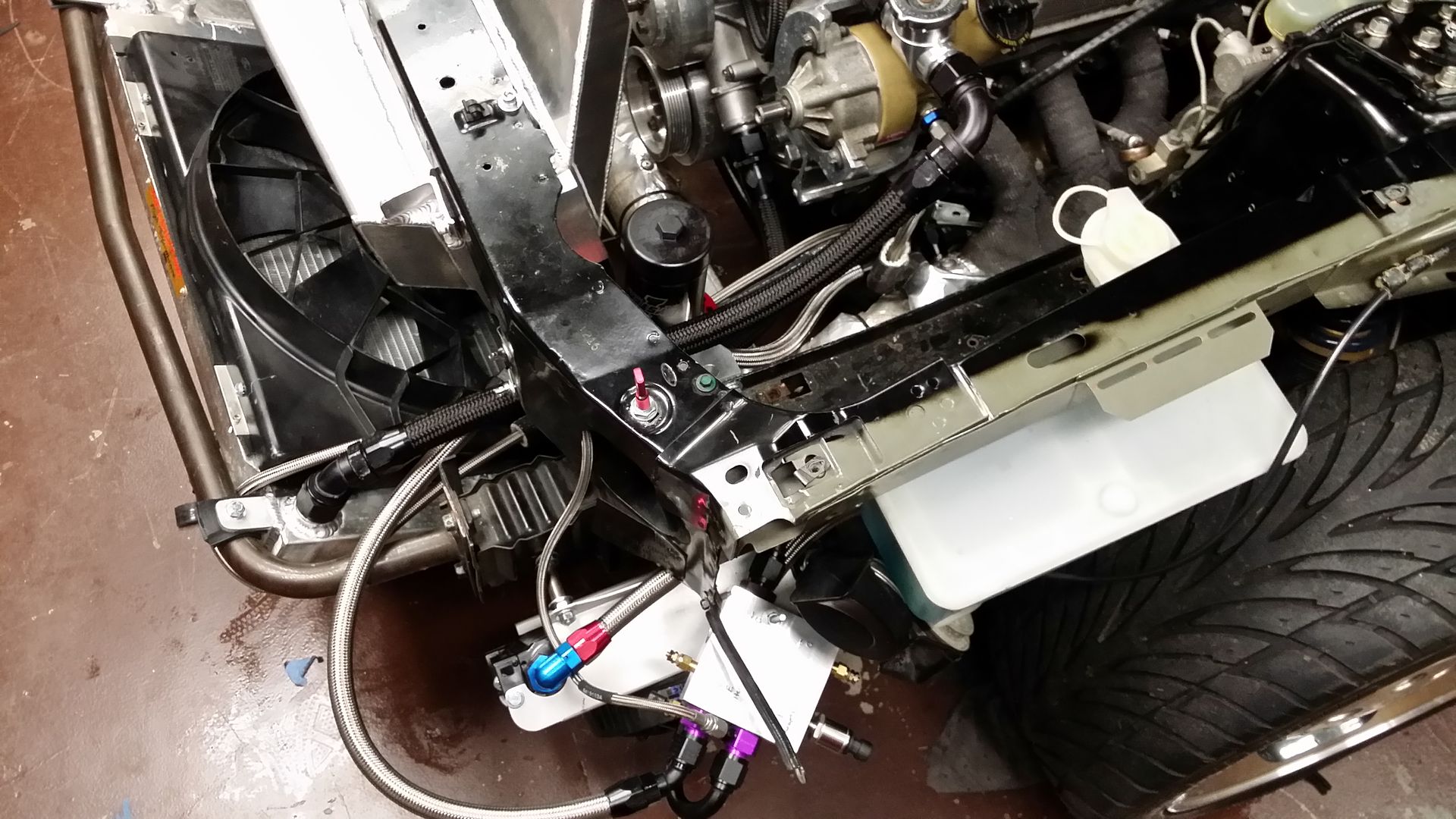

I got the car back and plumbed the coolant lines, mounted the oil filter, mounted the oil cooler and built the oil lines, mounted the power steering cooler.

Radiator's new home.

Hoses everywhere

There were a few let downs on the cooler though. The tapped the ends for a 3/8"npt instead of welding in a weld bung. Result? Their tap wouldn't go far enough in before hitting the cores and therefor I can only get the sensor to grab one thread. Not going to work. Might as well pull the cooler and have air temp sensors put in and the return water temp sensor put in too.

The bumper cover falls short of the lower core support by about 4". I figured that would be the case and am kicking around the theory of where the radiator gets its air from and whether or not to just to block the entire bottom off and take a mini splitter all the way back to the bottom of the radiator.

Fuck you. We're going to Costco.

Fuck you. We're going to Costco.

Comment

-

I didn't even think of a bottoming tap. Thanks. I still need to get the air temp sensor and coolant return sensor ported into the cooler.Originally posted by NoClassic View PostIf they already have the threads started you could try a bottoming tap to get some more depth before contacting the core. I sucks you had to use push through mounts on the PS cooler. Those things tear up cores pretty bad over time.

I cringed pushing those through mounts.Fuck you. We're going to Costco.

Comment

Comment