Why not just use some fiberglass to repair/reshape the current bezel? With minimal work it would make a huge improvement.

Announcement

Collapse

No announcement yet.

What I have been working on

Collapse

X

-

sigpic18 F150 Supercrew - daily

17 F150 Supercrew - totaled Dec 12, 2018

13 DIB Premium GT, M6, Track Pack, Glass Roof, Nav, Recaros - Sold

86 SVO - Sold

'03 F150 Supercrew - Sold

01 TJ - new toy - Sold

65 F100 (460 + C6) - Sold

Comment

-

Originally posted by kbscobravert View PostThanks guys. I had to do daddy things today. Birthday party for a friends 1yr old and early dinner at my MIL's. Plus we got in late last night.Spent today at the river with good friends and lots of guns and ammo. (http://s1018.photobucket.com/user/MD2595/media/LR-0174_zps9688f446.jpg.html) (http://s1018.photobucket.com/user/MD2595/media/LR-0036_zpsd7a92acc.jpg.html) (http://s1018.photobucket.com/user/MD2595/media/LR-9502_zps73cdba83.jpg.html)

Just in case you missed it!

Comment

-

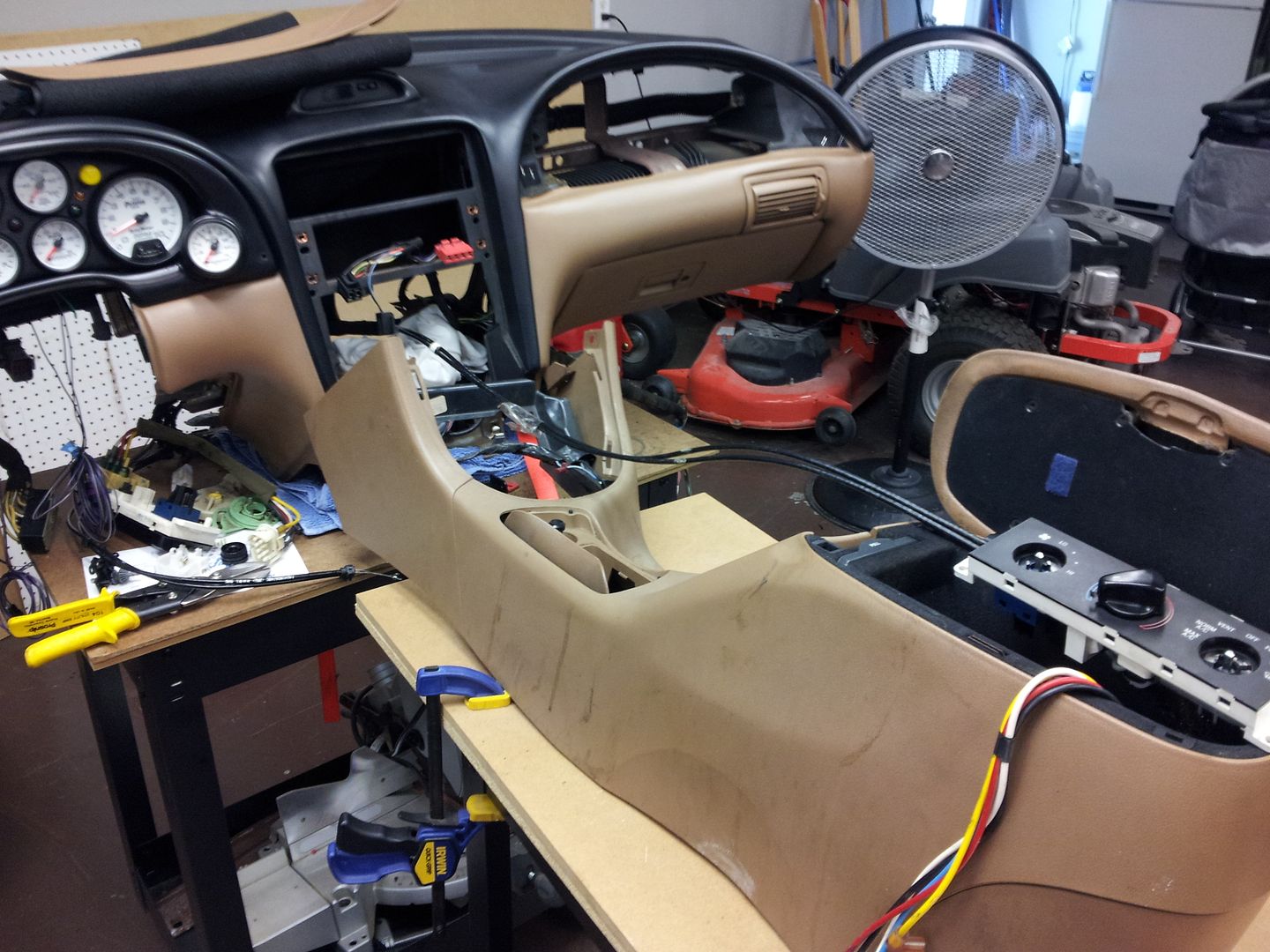

Worked on some gauges stuff......again. Working on my mock up interior parts.

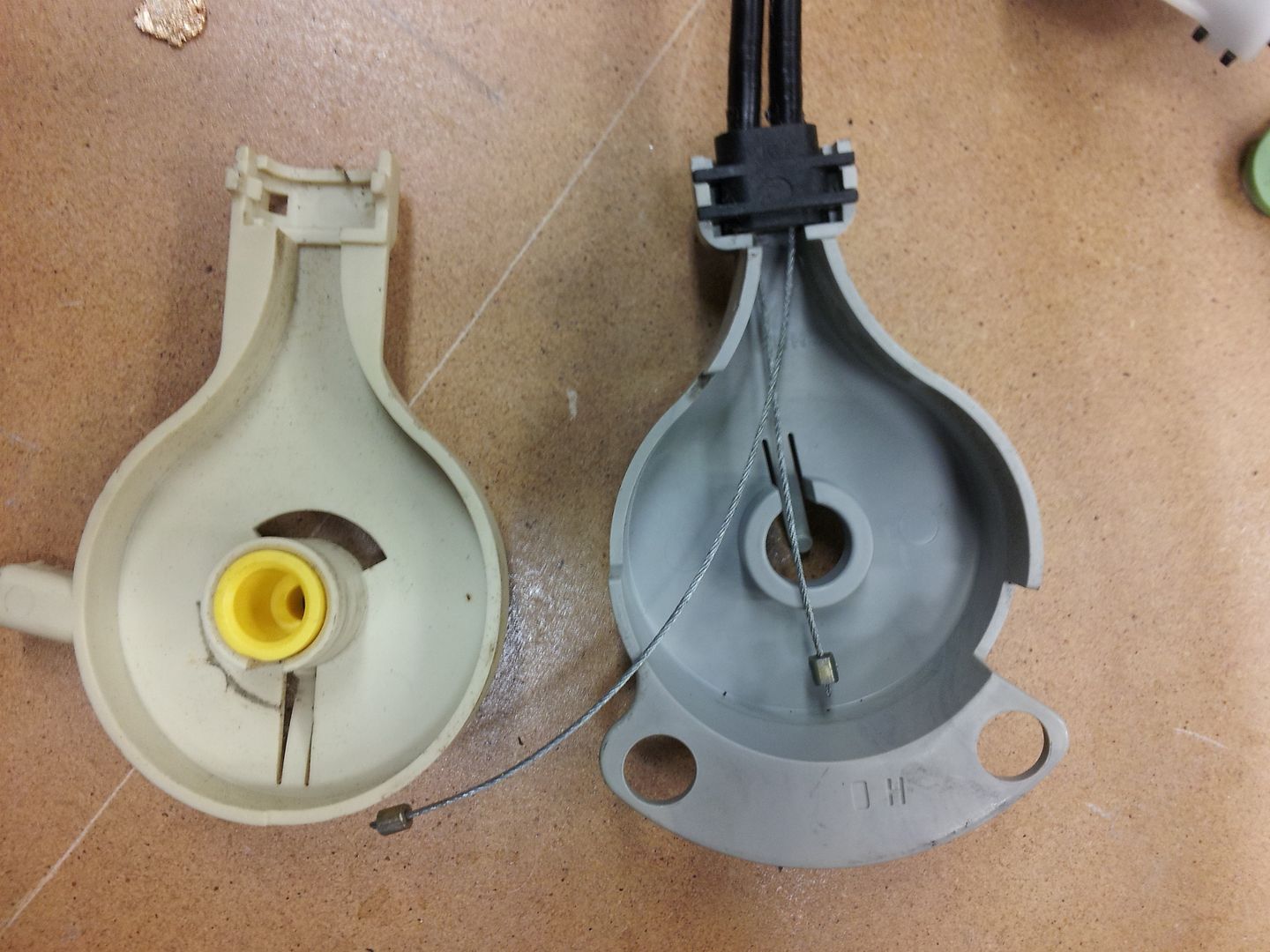

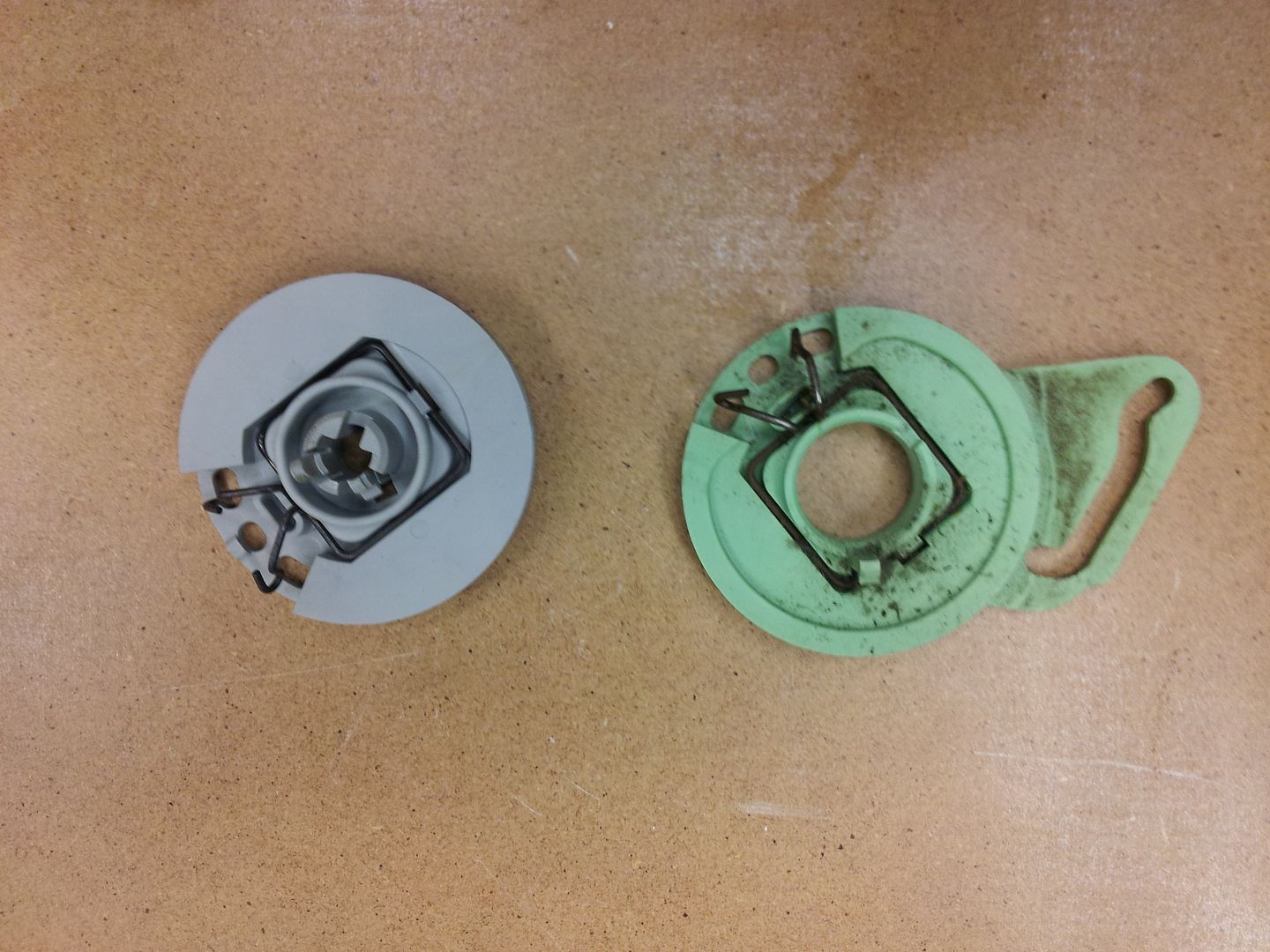

Next up. I still need to put the Fuel PSI, Boost and AFR. So I am moving the HVAC controls to the center console and out of sight. For a cable driven blend door; how? Well, Ford uses the same style push/pull cable for their HVAC controls for a lot of years. Hell, the HVAC switch panel is the same between most of their models in my years. So I found a truck with a cable long enough to move the controls to wherever I want. It is a little more difficult than that but I won't bore you with the details.

So here is the mock ups.

The part that bolts to the blend door is clocked different and along with a few other differences but the cables a cable is a cable, etc.

So I swapped all the mustang parts over to the truck cables. Actually easier than I thought. I just need to shorten one of the ends though. A simple aluminum ferrel crimp will fix that.

Put the gauges in there to see how they will look, sort of.

Fuck you. We're going to Costco.

Fuck you. We're going to Costco.

Comment

-

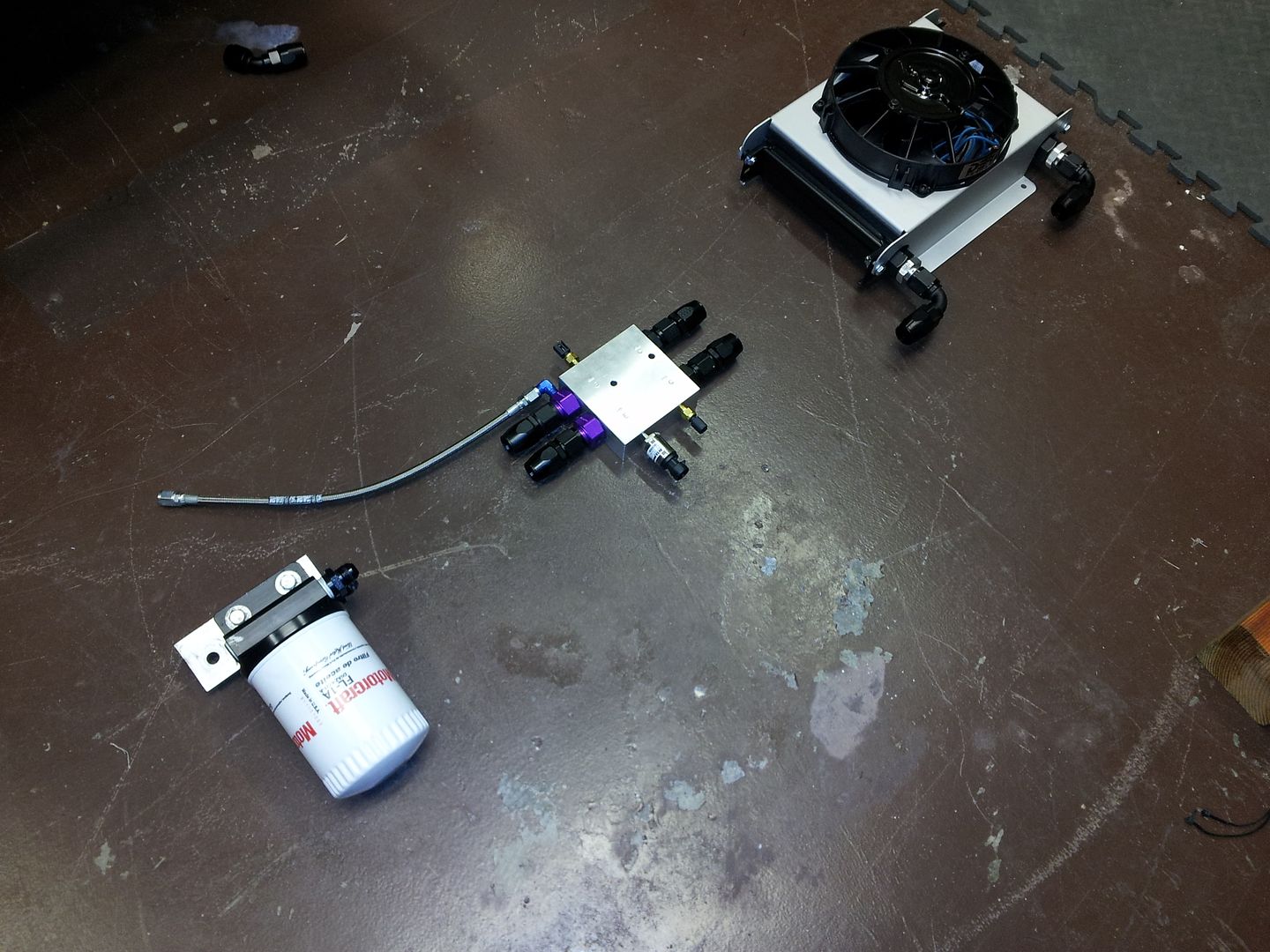

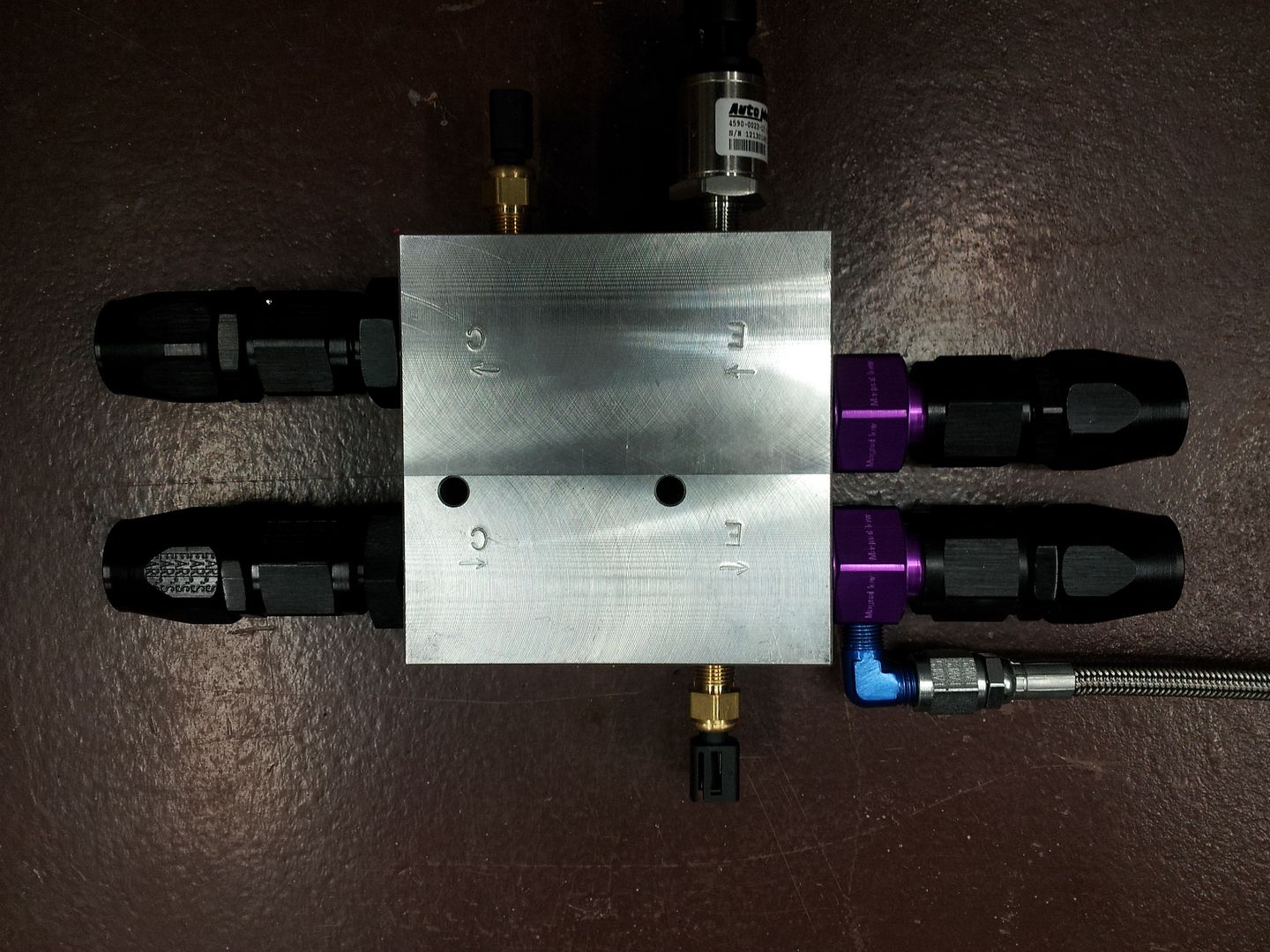

Planning out the oil cooler w/thermostat and all the other shit that the car needs tapped into the oil lines.

Swapped everything over to -10an vs the original -8an lines. Learned that running an oil cooler without a thermostat is NO GOOD. Tie in the ethanol fuel and the oil gets too much vapor.

Now just got to find where to put all this shit.

Oil filter bracket bolts to the bell housing since my headers face the wrong way........plenty of room. Hell, I can run a taller oil filter now too.

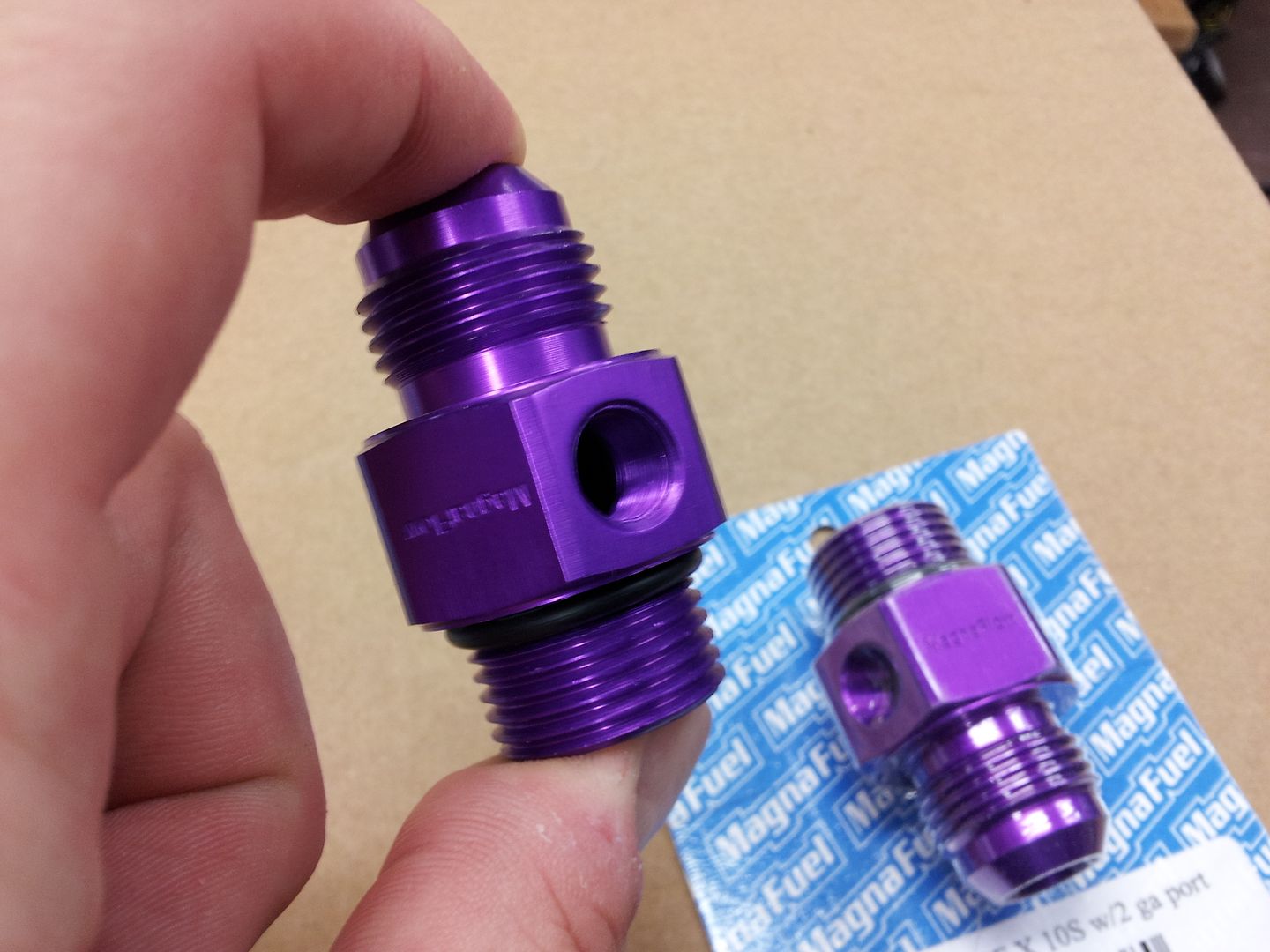

Bracket is just a simple piece but the mount is a nice Canton. Bad thing is, it uses 1/2"npt vs -10an and without drilling it and tapping for 1/8"npt I have to find adapters. For every problem there is a solution. As always, money fixes everything and a lot of times it can be done with just the right fitting. Well how about these?

And the thermostat is pretty busy. Oil feed for the turbo. Pre and post temp sensors. Oil PSI sender.

I think I am going to make a simple plate mounted to the K-member with some u-bolts then bolt the thermostat to it.Fuck you. We're going to Costco.

Comment

-

-

It's called dwell time... and he has lots of it!Originally posted by bird_dog0347 View PostVery nice, I love how you plan all this out and seem to stick to it. But I guess that's a little easier to do when you're away from the car for months at a time.Originally posted by PGreenCobraI can't get over the fact that you get to go live the rest of your life, knowing that someone made a Halloween costume out of you. LMAO!!Originally posted by Trip McNeelyGo do a whooly in front of a Peterbilt.Originally posted by dsrtuckteezydont downshift!!

Comment

Comment