Originally posted by Ruffdaddy

View Post

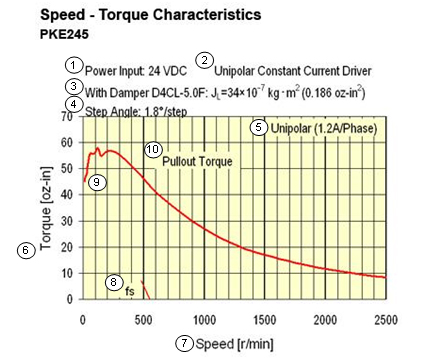

Edit: The advantage of an electric motor is that the torque curve is nearly completely linear. There are some outside factors that can change that. For example most electric cars switch the motor on and off via pulse-width modulation as a way of throttling the motor. Throttling it through limiting current is also another method.

Comment