Looks like a real piece of s.

With all the buzz surrounding electric cars, it’s worth remembering that internal combustion engines remain an active area of technology development. For example, a Michigan-based start-up called EcoMotors has created a new type of engine that could improve fuel economy by 20% compared to conventional turbo diesel engines—and be built at a lower production cost. Yesterday, EcoMotors announced the creation of a joint venture to start building these engines in China.

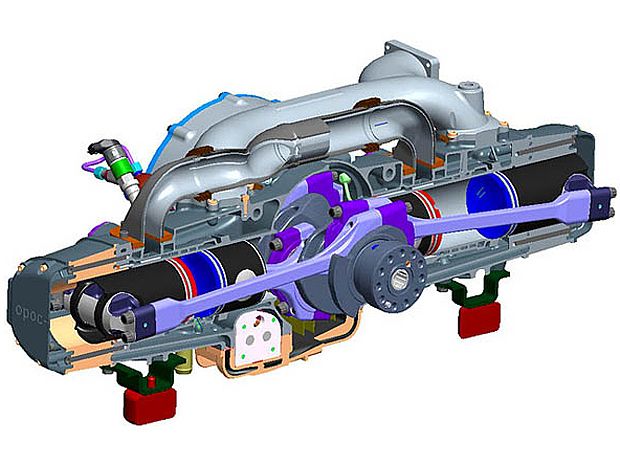

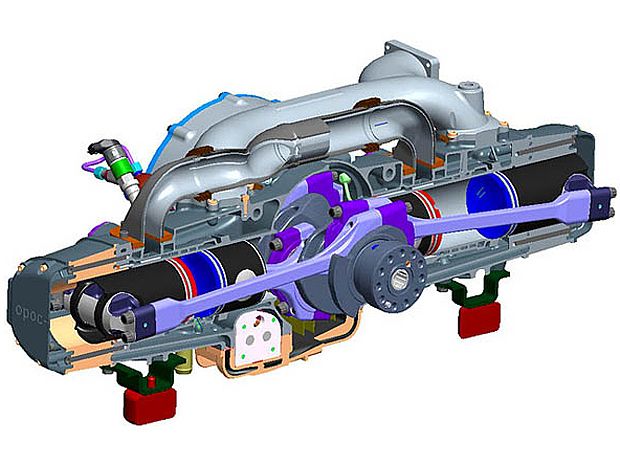

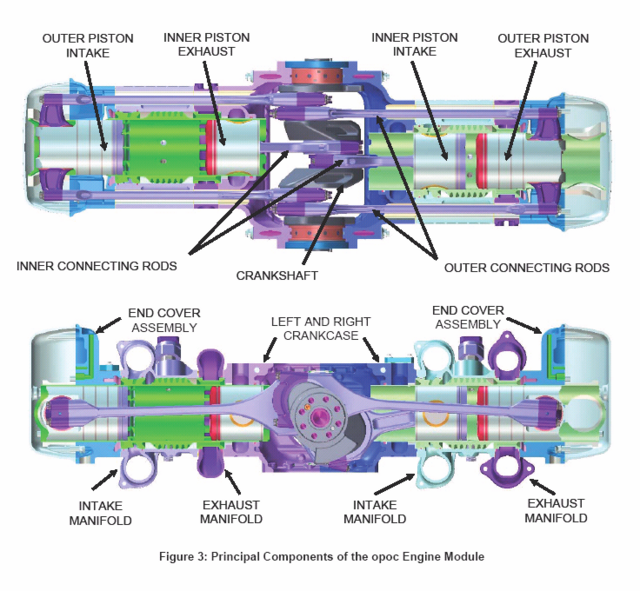

The company's Opoc engine breaks with conventional designs in a number of ways to reduce weight and volume while saving fuel. It has two cylinders, which each house two pistons. That increases the power density because pistons need to travel half the distance, according to the company. The two-stroke engine also uses electrical control systems in place of mechanical components to precisely regulate combustion, it says.

An electrically controlled clutch, for example, allows the engine to operate with both two-cylinder modules operating, or with one turned off to save fuel while driving. Although EcoMotors plans to initially manufacture diesel engines, the basic architecture can also work with gasoline, natural gas, or biofuels.

With serious air-quality problems and government mandates for fuel efficiency, China represents a large market for this type of technology. "For customers in China, it will ultimately provide access to affordable technology that will have a positive influence on the country’s transportation emissions,” said EcoMotors' president Amit Soman in a statement.

Automakers around the world are making a number of incremental changes to internal combustion engines to meet fuel efficiency mandates. Ford Motor's EcoBoost, for example, uses a turbo and direct injection to improve efficiency and power density. At the same time, there are number of companies pursuing completely new engine designs. In addition to EcoMotors, other start-ups include Grail Engine Technologies, Achates Power, Liquid Piston, and Pinnacle Engines.

As a company, six-year-old EcoMotors has had a relatively quick journey from company founding to commercialization, although it's been a slightly different path than first envisioned. When I spoke to CEO Donald Runkle four years ago, he envisioned bringing the engine to market by licensing the technology to U.S. automakers or making engines itself.

Instead, an affiliate of Chinese automaker First Auto Works Group will finance construction of a $US 200-million plant to start manufacturing 100 000 engines per year with EcoMotors opposed piston design. With the deal, EcoMotors, which attracted investment from Bill Gates and Khosla Ventures, will see its novel technology come to life at large-scale next year.

For many energy technology companies, China offers a very large market and a place where government policies make it feasible to raise the capital required to build manufacturing plants or large-scale demonstration projects. “This partnership will demonstrate how (EcoMotors) technology can be developed and delivered practically to important and growing markets,” investors William Lese said in a statement. Last April, EcoMotors signed a separate deal with to build an engine plant with auto parts conglomerate Zhongding Power in China.

With all the buzz surrounding electric cars, it’s worth remembering that internal combustion engines remain an active area of technology development. For example, a Michigan-based start-up called EcoMotors has created a new type of engine that could improve fuel economy by 20% compared to conventional turbo diesel engines—and be built at a lower production cost. Yesterday, EcoMotors announced the creation of a joint venture to start building these engines in China.

The company's Opoc engine breaks with conventional designs in a number of ways to reduce weight and volume while saving fuel. It has two cylinders, which each house two pistons. That increases the power density because pistons need to travel half the distance, according to the company. The two-stroke engine also uses electrical control systems in place of mechanical components to precisely regulate combustion, it says.

An electrically controlled clutch, for example, allows the engine to operate with both two-cylinder modules operating, or with one turned off to save fuel while driving. Although EcoMotors plans to initially manufacture diesel engines, the basic architecture can also work with gasoline, natural gas, or biofuels.

With serious air-quality problems and government mandates for fuel efficiency, China represents a large market for this type of technology. "For customers in China, it will ultimately provide access to affordable technology that will have a positive influence on the country’s transportation emissions,” said EcoMotors' president Amit Soman in a statement.

Automakers around the world are making a number of incremental changes to internal combustion engines to meet fuel efficiency mandates. Ford Motor's EcoBoost, for example, uses a turbo and direct injection to improve efficiency and power density. At the same time, there are number of companies pursuing completely new engine designs. In addition to EcoMotors, other start-ups include Grail Engine Technologies, Achates Power, Liquid Piston, and Pinnacle Engines.

As a company, six-year-old EcoMotors has had a relatively quick journey from company founding to commercialization, although it's been a slightly different path than first envisioned. When I spoke to CEO Donald Runkle four years ago, he envisioned bringing the engine to market by licensing the technology to U.S. automakers or making engines itself.

Instead, an affiliate of Chinese automaker First Auto Works Group will finance construction of a $US 200-million plant to start manufacturing 100 000 engines per year with EcoMotors opposed piston design. With the deal, EcoMotors, which attracted investment from Bill Gates and Khosla Ventures, will see its novel technology come to life at large-scale next year.

For many energy technology companies, China offers a very large market and a place where government policies make it feasible to raise the capital required to build manufacturing plants or large-scale demonstration projects. “This partnership will demonstrate how (EcoMotors) technology can be developed and delivered practically to important and growing markets,” investors William Lese said in a statement. Last April, EcoMotors signed a separate deal with to build an engine plant with auto parts conglomerate Zhongding Power in China.

Comment