Originally posted by dsrtuckteezy

View Post

Announcement

Collapse

No announcement yet.

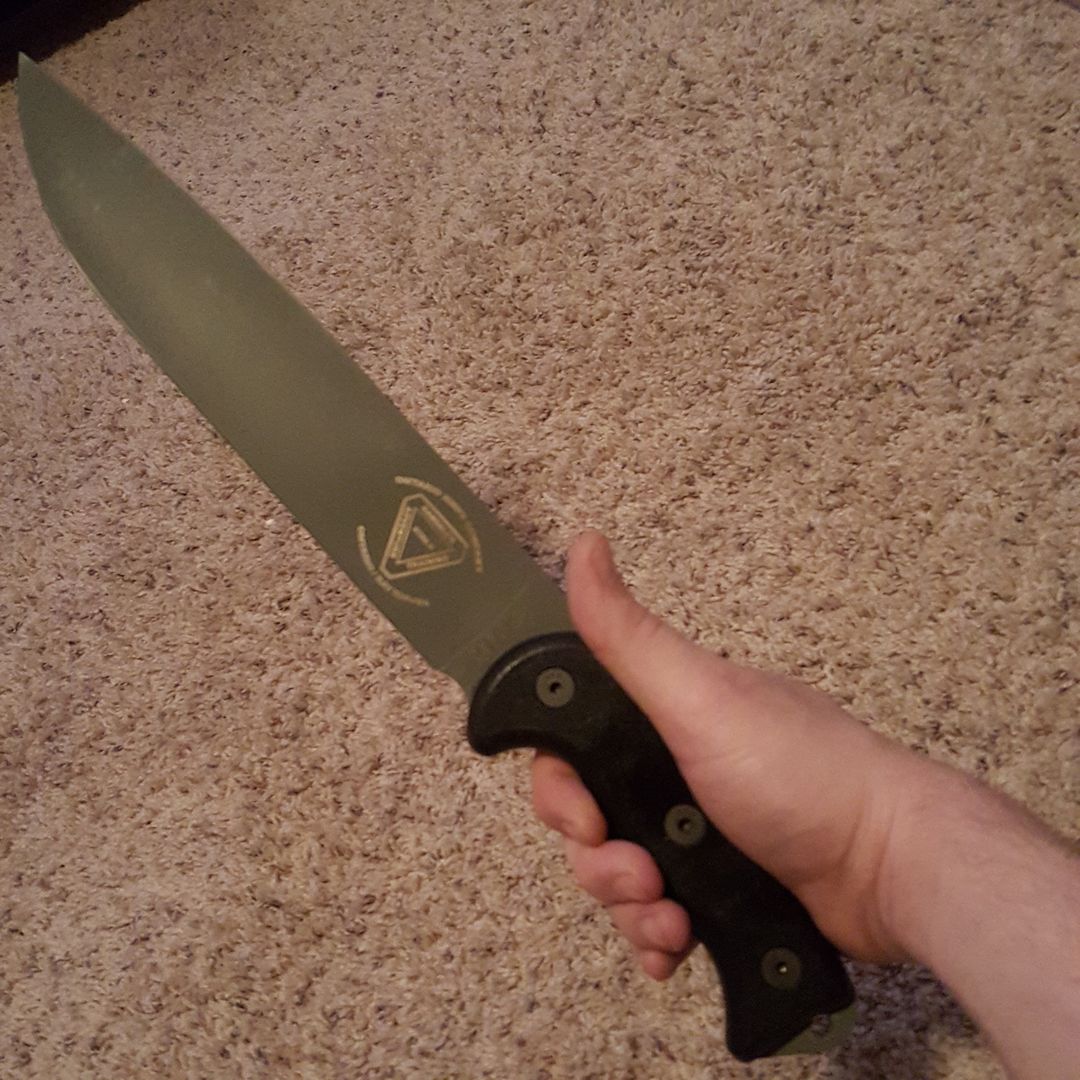

Survival knife

Collapse

X

-

The old (pre-Vietnam) Kabars were tough to beat. But, you're doing it right. In the truest sense, that is an excellent survival knife.Originally posted by dsrtuckteezy View PostI like my mk3 mod0 better than my kabar"It is in truth not for glory, nor riches, nor honours that we are fighting, but for freedom - for that alone, which no honest man gives up but with life itself."

Comment

-

I don't have just one. I have knives and machetes to cover all tasks.

Kershaw

Cold Steel

Kbar

Etc."Laws that forbid the carrying of arms...disarm only those who are neither inclined nor determined to commit crimes...Such laws make things worse for the assaulted and better for the assailants; they serve rather to encourage than to prevent homicides, for an unarmed man may be attacked with greater confidence than an armed man." - Thomas Jefferson, 1776

Comment

-

Pretty long video, but a very telling torure test, and surprising results for a $10 knife..Originally posted by Danny46 View Post+1 on the mora knife. I have one and it is a great knife especially considering the price, best bang for buck knife out there IMO. I've used mine to field dress an animal, cut cordage etc.

Comment

-

Comment

I have both a Benchmade Nimravus and a Contego, a NY KaBar, an SOG Trident, a Lonewolf fixed blade of some kind, and a bunch of other shit. I've kind of abused the piss out of my employee discount at this gun store.ZOMBIE REAGAN FOR PRESIDENT 2016!!! heh

Comment

Good article right here explaining and comparing the different metals used in knives.

Check out our essential guide to knife steel as we discuss the most popular steels and the key factors to consider in choosing the best steel for your knife.

Check out our essential guide to knife steel as we discuss the most popular steels and the key factors to consider in choosing the best steel for your knife.

quick excerpt

[QUOTE]In choosing the best pocket knife you should pay particular attention to the type of steel used in the blade. Steel is really the essence of the blade and primarily responsible for how the knife performs. Steel is essentially an alloy (i.e. a mix) of carbon and iron that is often enriched with other elements to improve certain characteristics depending on the desired application.

In the knife industry different types of steel are created by varying the types of additive elements as well as how the blade is rolled and heated (i.e. the finishing process). Refer to our Knife Steel Composition Chart for more details on these elements.

Ultimately, the different types of steel used in knife blades each exhibit varying degrees of these five key properties:

Hardness

logocircle-smallHardness is the ability to resist deforming when subject to stress and applied forces. Hardness in knife steels is often referred to as strength and is generally measured using the Rockwell C scale (aka “HRC”).

Toughness

logocircle-smallToughness is the ability to resist damage like cracks or chips when being used in heavy duty applications. This also defines the steel’s ability to flex without breaking. Note that the stronger or harder the steel the less tough it will likely be. Note the measurement of toughness is less standardized as hardness.

Wear Resistance

logocircle-smallWear resistance is the steel’s ability to withstand damage from both abrasive and adhesive wear. Abrasive wear comes from softer surfaces coming in contact with rougher ones. Adhesive wear occurs when debris is dislodged from one surface and attaches to the other. Wear resistance generally correlates with the steel’s hardness but is also heavily influenced by the specific chemistry of the steel. In steels of equal hardness, the steel with larger carbides (think microscopic, hard, wear resistant particles) will typically resist wear better.

Corrosion Resistance

logocircle-smallCorrosion resistance is the ability to resist corrosion such as rust caused by external elements like humidity, moisture and salt. Note that a high resistance to corrosion does involve a sacrifice in the overall edge performance.

Edge Retention

logocircle-smallEdge Retention represents how long the blade will retain its sharpness when subject to periods of use. It’s what everyone talks about these days but unfortunately the measurement of edge retention lacks any defined set of standards and so much of the data is subjective. For me, edge retention is a combination of wear resistance and an edge that resists deformation.

Unfortunately the “best knife steel” is not simply a case of maximizing each of the properties above….it’s a trade off. The biggest trade off is balancing strength or hardness with toughness. Some blades can be made to be exceptionally hard but will chip or crack if you drop them onto a hard surface. Conversely a blade can be extremely tough and able to bend but will struggle to hold it’s edge. Also note that the term ‘stainless steel‘ is generally misleading as all types of steel will show some kind of discoloration if left exposed to the elements for long enough. By knowing how you plan to use the knife you will generally be able to determine the best steel for your situation./QUOTE]

Comment

Powered by vBulletin® Version 5.7.5

Copyright © 2025 MH Sub I, LLC dba vBulletin. All rights reserved.

Copyright © 2025 MH Sub I, LLC dba vBulletin. All rights reserved.

All times are GMT-6. This page was generated at 08:33 AM.

Working...

X

Comment