only problem i see is that it looks like you are using a 4in downpipe, i'll need to run a 5" pipe

Announcement

Collapse

No announcement yet.

My LSx Coupe Build

Collapse

X

-

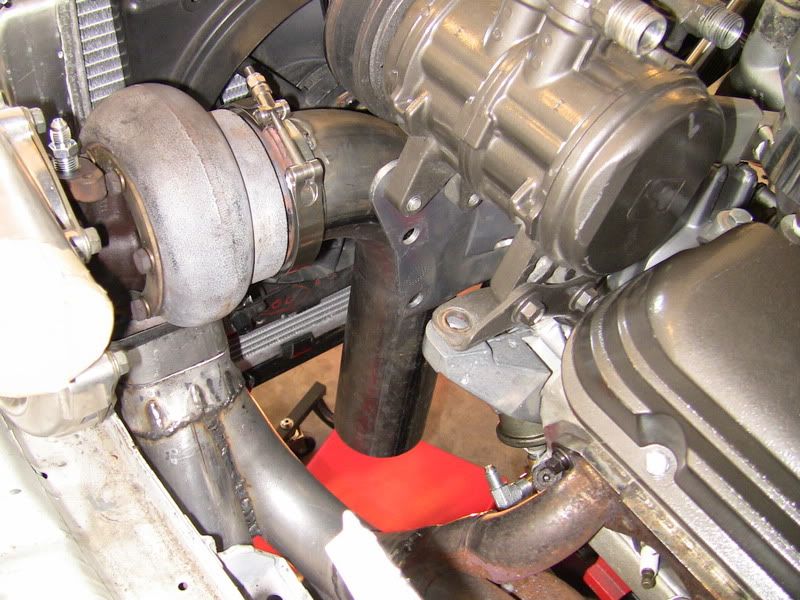

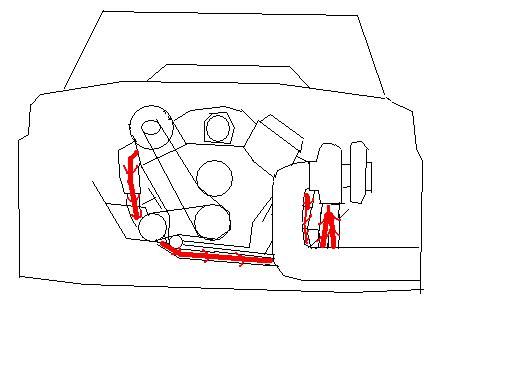

Correct, that's a 3.5 or 4" downpipe AND a T4 turbo.

The [main] problem is that the downpipe uses about 9.5" of space from the leading edge of the bend to the backside of the pipe (on a 90* bend). On a Ford engine/waterpump - that's ALL of the space that's available. Usually you have to tilt the downpipe outward some (think: more than 90* bend) to make that work... The LS engine appears to have a wider/bigger diameter waterpump pulley - makes it MORE of a problem.

Comment

-

what about just notching the inside of the frame for the t6 flange which would push the whole turbo towards the outside of the car, then the output of the compressor would be on the outside of the frame rail and you'd just have to cut a hole in the bottom of the apron. i can only squeeze about another inch or so before the flange hits the inside of the frame rail and there is no way a 5" bend is going to clear everything (even with the additional inch)Originally posted by turbostang View PostCorrect, that's a 3.5 or 4" downpipe AND a T4 turbo.

The [main] problem is that the downpipe uses about 9.5" of space from the leading edge of the bend to the backside of the pipe (on a 90* bend). On a Ford engine/waterpump - that's ALL of the space that's available. Usually you have to tilt the downpipe outward some (think: more than 90* bend) to make that work... The LS engine appears to have a wider/bigger diameter waterpump pulley - makes it MORE of a problem.

Comment

-

You WANT the flange against the inside of the frame. It should mount to the pinch weld. Besides, what's the difference between cutting the outside of the frame and the inside?Originally posted by dville_gt View Postwhat about just notching the inside of the frame for the t6 flange which would push the whole turbo towards the outside of the car, then the output of the compressor would be on the outside of the frame rail and you'd just have to cut a hole in the bottom of the apron. i can only squeeze about another inch or so before the flange hits the inside of the frame rail and there is no way a 5" bend is going to clear everything (even with the additional inch)

Comment

-

more room for the downpipe, the further outboard i get it the more room inboard i have for the 5" 90*Originally posted by turbostang View PostYou WANT the flange against the inside of the frame. It should mount to the pinch weld. Besides, what's the difference between cutting the outside of the frame and the inside?

Comment

-

the coupe had a good night at the cruise, didn't get the 6.9x i was looking for, but she has been dead consistent the last two times out. last 5-6 runs have all been 7.0x's @ ~98. made it into the brackets but had to bow out early due to a broken alternator bolt that allowed the alternator to shift and caused a horrendous belt slip squeal. got the track official to spray it down with vht hoping i could make it a few more runs but it just made the squeal worse so i decided to head home before i got stranded at the track. now she is on the chopping block getting ready for the turbo. so long 7's!

here are some videos of her last n/a trip to the track.

same run, slightly different view

Comment

-

ya, need some boost and an anti roll bar! might have got some air under the fronts if it weren't for the terrible roll to the passenger side! car did 1.5 60's every run. matter of fact the car had pretty much identical runs every pass, same 60', et, mph, etc. i thought it was strange cause the first pass out showed to be very rich (like 11.8:1) so i took a bunch of fuel out, next run was better but still about 6-8% rich, took more fuel out and got it pretty much dead on @ 12.8:1, never picked up any et or mph though. you'd think leaning it out a full point would have been worth something!Originally posted by 2165 Turbo Rail View Postlooks good in the vids can't wait to see what it will do with some boost

Comment

Comment