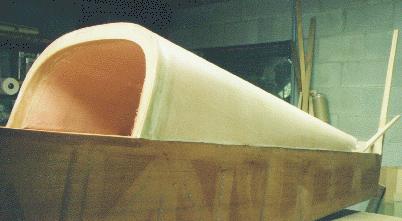

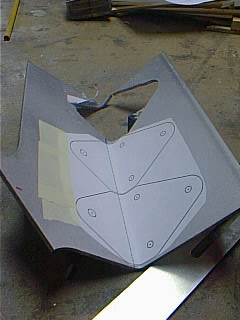

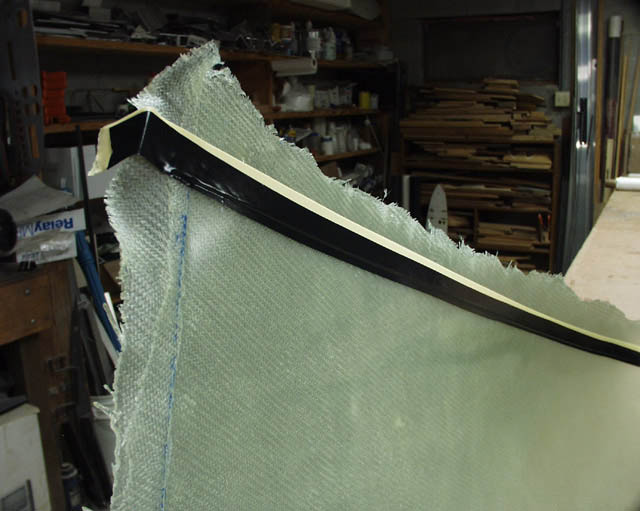

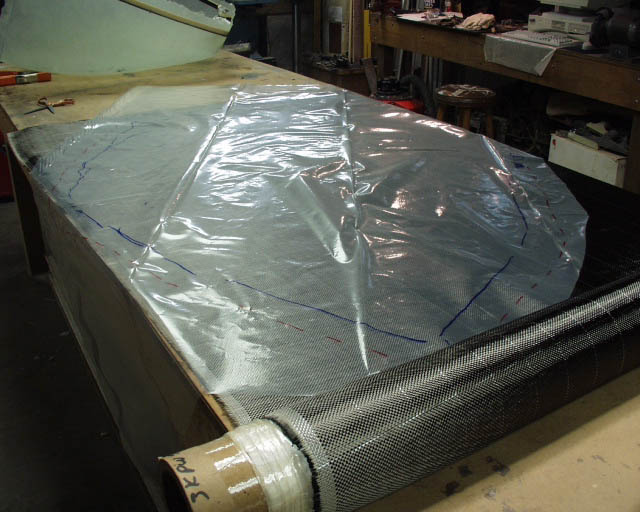

One layer of 5.85 oz fiberglass was applied to the inside surface of the deck, along with a few additional plies in the vicinity of the roll bar. The roll bar is basically a 2" x 2" curved box beam, with about 6 layers of 9 oz cloth on each of the four sides. Trying to squeeze the two legs of the C together with about 50 lbs of force yields maybe .1" of deflection. This mama is STRONG!

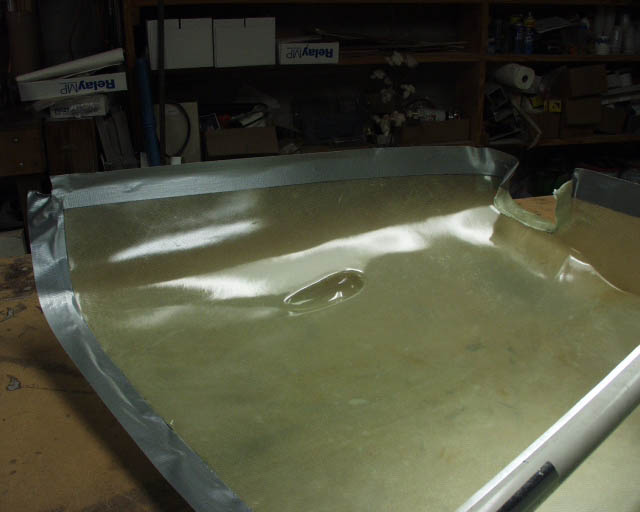

The end result. Perfection has been achieved, at least close enough for KR work. The end result weighs 9 pounds, including integral roll bar.

Comment