Man those smittybilt armor fenders are getting so overdone on JK's these days.

Announcement

Collapse

No announcement yet.

Pictures of your work?

Collapse

X

-

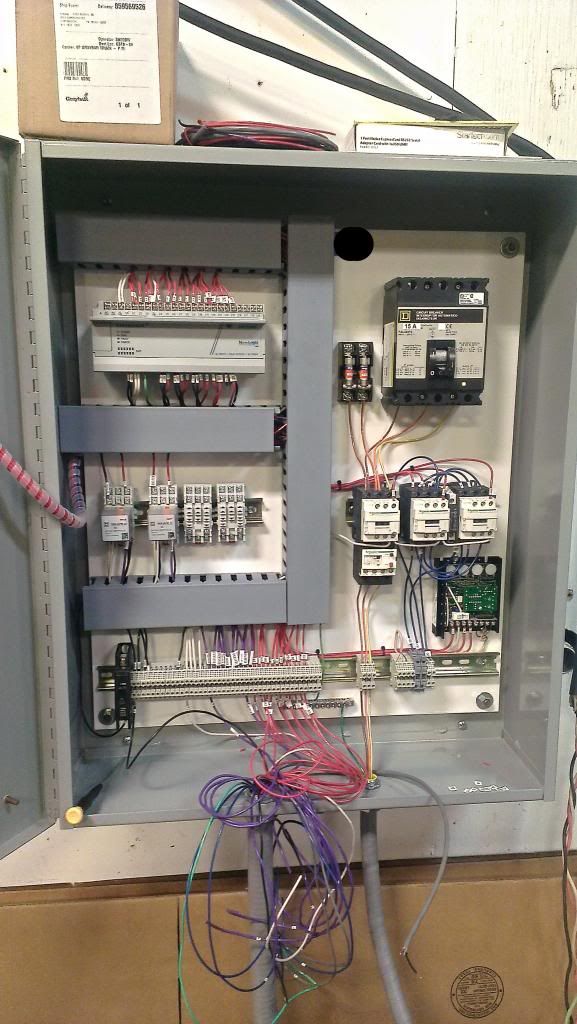

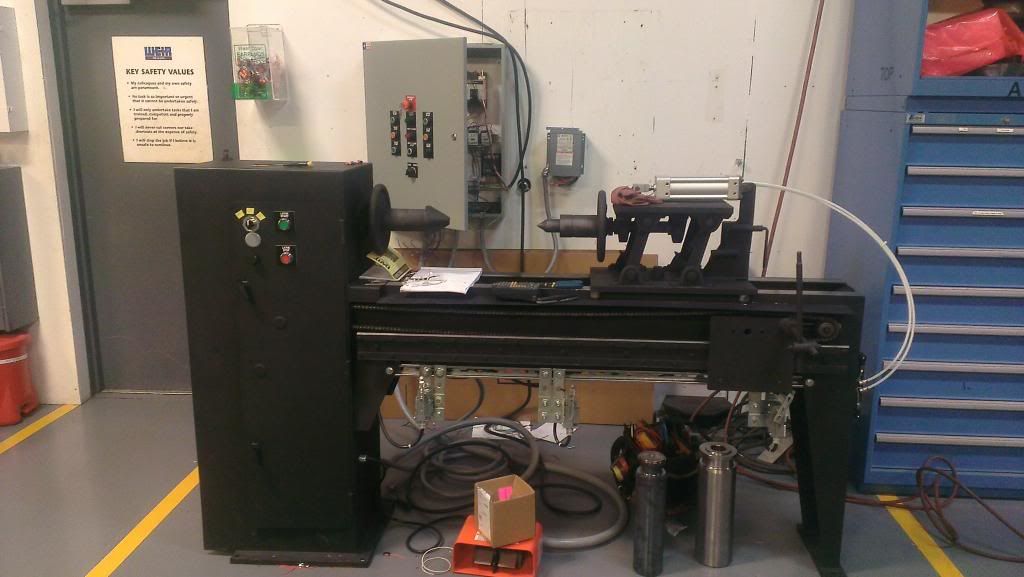

This is my first PLC job since school.

It's for a heat treating and coating process of a plunger for frac pumps.

The part is heated to 400F, coated, and then heated to 1400F. Originally a guy stood there holding two torches while the the part turned on the lathe. It was hot work for the guy. The maintenance men mounted these limit switches and I did the rest.

A torch now is mounted to that square piece of steel and upon selecting "run" the torch will leave the first limit switch and bounce back and fourth between the 2nd and 3rd limit switch until the desired heat is achieved. Initially it sounded pretty simple but for a bit complicated faily quickly.

I added a DC controller and a pot to control the speed of the torch.

I built in a couple safties too. For example, the lathe cannot drop the part with it's running, yada yada yada.

Pretty rewarding adventure when all was said and done.

[the incoming wires are temped in]

DE OPPRESSO LIBER

DE OPPRESSO LIBER

Comment

-

I work for a contractor. We've been out there for three years now almost daily.Originally posted by Andy@PrimeTuning View PostI see you are at SPM

I hope you design works great and they send you around to all locations building one.

They only have three of these. 2 here and one in Houston. I may be retrofitting the other two, but that's it.DE OPPRESSO LIBER

Comment

Comment